Technology peripherals

Technology peripherals AI

AI The innovative path of digital continuity: Agile, swift and intelligent applications of robot digital twins

The innovative path of digital continuity: Agile, swift and intelligent applications of robot digital twinsThe innovative path of digital continuity: Agile, swift and intelligent applications of robot digital twins

In an era of digital transformation and changing consumer demands, manufacturing companies recognize that they need to increase agility and flexibility to ensure business continuity. Many companies are already leveraging digital solutions and robots to improve efficiency, reduce costs and enhance competitiveness. While this is a step in the right direction, there are still many challenges in achieving seamless digital integration that prevent manufacturers from realizing the full potential of their solutions

When companies realize that these challenges stem from a lack of digital continuity between manufacturing processes, teams, business partners, and IT systems, they turn to robotic digital twins for help bridging the gap.

01 Seize the opportunity and use robot twins

Robot digital twin is an important link between the virtual world of design and process engineering and the real world of production, facilitating the seamless flow of information, data and knowledge, allowing users to gain relevant Comprehensive integrated view of the entire manufacturing process.

02 Use DELMIA robots to enhance competitiveness

Highly developed internet connection

The system automatically updates any changes to the product design to the robot's trajectory, and also takes into account changes to the process plan so that every operation of the product is displayed in actual application

A solution that works for all robots:

DELMIA robot solutions are suitable for multiple manufacturers and are compatible with various robot systems to enable the design, programming, simulation and control of different types of robots

Adopt 3DEXPERIENCE Platform to enhance collaboration:

DELMIA robots run on the Dassault Systèmes3DEXPERIENCE platform, which consolidates all information into a single data source. Stakeholders, including non-experts (managers and salespeople), can view work cells via a web client without a Robot license.

Share and retain knowledge:

Stakeholders globally can collaborate to create and share template work cells to enable cross-factory standard setting

03 Realizing the actual benefits of DELMIA robot

Windsor Limited is the centerline.

Windsor Limited is the centerline. is a Canadian company specializing in advanced automated processes and joining technologies for resistance welding, metal forming and cold spray applications. They leverage DELMIA robots on the3DEXPERIENCE platform to simulate products, processes and factory operations before actual deployment to avoid design errors. This allows them to show customers how new products and processes can give them a competitive advantage while unlocking the following benefits:

• save time• Reduced tooling related issues and rework by up to 90%

• Reduce programming time by up to 25%

The above is the detailed content of The innovative path of digital continuity: Agile, swift and intelligent applications of robot digital twins. For more information, please follow other related articles on the PHP Chinese website!

How to Run LLM Locally Using LM Studio? - Analytics VidhyaApr 19, 2025 am 11:38 AM

How to Run LLM Locally Using LM Studio? - Analytics VidhyaApr 19, 2025 am 11:38 AMRunning large language models at home with ease: LM Studio User Guide In recent years, advances in software and hardware have made it possible to run large language models (LLMs) on personal computers. LM Studio is an excellent tool to make this process easy and convenient. This article will dive into how to run LLM locally using LM Studio, covering key steps, potential challenges, and the benefits of having LLM locally. Whether you are a tech enthusiast or are curious about the latest AI technologies, this guide will provide valuable insights and practical tips. Let's get started! Overview Understand the basic requirements for running LLM locally. Set up LM Studi on your computer

Guy Peri Helps Flavor McCormick's Future Through Data TransformationApr 19, 2025 am 11:35 AM

Guy Peri Helps Flavor McCormick's Future Through Data TransformationApr 19, 2025 am 11:35 AMGuy Peri is McCormick’s Chief Information and Digital Officer. Though only seven months into his role, Peri is rapidly advancing a comprehensive transformation of the company’s digital capabilities. His career-long focus on data and analytics informs

What is the Chain of Emotion in Prompt Engineering? - Analytics VidhyaApr 19, 2025 am 11:33 AM

What is the Chain of Emotion in Prompt Engineering? - Analytics VidhyaApr 19, 2025 am 11:33 AMIntroduction Artificial intelligence (AI) is evolving to understand not just words, but also emotions, responding with a human touch. This sophisticated interaction is crucial in the rapidly advancing field of AI and natural language processing. Th

12 Best AI Tools for Data Science Workflow - Analytics VidhyaApr 19, 2025 am 11:31 AM

12 Best AI Tools for Data Science Workflow - Analytics VidhyaApr 19, 2025 am 11:31 AMIntroduction In today's data-centric world, leveraging advanced AI technologies is crucial for businesses seeking a competitive edge and enhanced efficiency. A range of powerful tools empowers data scientists, analysts, and developers to build, depl

AV Byte: OpenAI's GPT-4o Mini and Other AI InnovationsApr 19, 2025 am 11:30 AM

AV Byte: OpenAI's GPT-4o Mini and Other AI InnovationsApr 19, 2025 am 11:30 AMThis week's AI landscape exploded with groundbreaking releases from industry giants like OpenAI, Mistral AI, NVIDIA, DeepSeek, and Hugging Face. These new models promise increased power, affordability, and accessibility, fueled by advancements in tr

Perplexity's Android App Is Infested With Security Flaws, Report FindsApr 19, 2025 am 11:24 AM

Perplexity's Android App Is Infested With Security Flaws, Report FindsApr 19, 2025 am 11:24 AMBut the company’s Android app, which offers not only search capabilities but also acts as an AI assistant, is riddled with a host of security issues that could expose its users to data theft, account takeovers and impersonation attacks from malicious

Everyone's Getting Better At Using AI: Thoughts On Vibe CodingApr 19, 2025 am 11:17 AM

Everyone's Getting Better At Using AI: Thoughts On Vibe CodingApr 19, 2025 am 11:17 AMYou can look at what’s happening in conferences and at trade shows. You can ask engineers what they’re doing, or consult with a CEO. Everywhere you look, things are changing at breakneck speed. Engineers, and Non-Engineers What’s the difference be

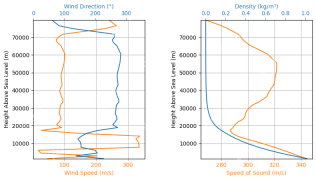

Rocket Launch Simulation and Analysis using RocketPy - Analytics VidhyaApr 19, 2025 am 11:12 AM

Rocket Launch Simulation and Analysis using RocketPy - Analytics VidhyaApr 19, 2025 am 11:12 AMSimulate Rocket Launches with RocketPy: A Comprehensive Guide This article guides you through simulating high-power rocket launches using RocketPy, a powerful Python library. We'll cover everything from defining rocket components to analyzing simula

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Atom editor mac version download

The most popular open source editor

SublimeText3 Linux new version

SublimeText3 Linux latest version

SublimeText3 Mac version

God-level code editing software (SublimeText3)

SublimeText3 English version

Recommended: Win version, supports code prompts!

SAP NetWeaver Server Adapter for Eclipse

Integrate Eclipse with SAP NetWeaver application server.