Technology peripherals

Technology peripherals AI

AI The founder of the robot company in 'The Wandering Earth 2': In the next 10 years, robots will rise!

The founder of the robot company in 'The Wandering Earth 2': In the next 10 years, robots will rise!The founder of the robot company in 'The Wandering Earth 2': In the next 10 years, robots will rise!

In "The Wandering Earth 2", there are about 22 robots appearing in different scenes. These intelligent robots are all from Youai Zhihe.

"But if you don't pay special attention to the robot, you won't even feel its existence, and there is no violation. In the words of director Guo Fan, reality is already very science fiction." Youai Zhihe said Robot founder and CEO Zhang Chaohui.

After 2017, the entire robot industry exploded rapidly, and basically every robot company ushered in rapid growth. In the past six years, UAI Zhihe has doubled its growth every year, and its penetration rate has increased rapidly in different industries.

Zhang Zhaohui said, "In fact, every product used in the movie has been shipped in batches in reality." "Roboticization in many industries has almost become a relatively inevitable trend."

How far has the robot industry developed? What is the underlying logic of the industry? How will the future impact your industry?

How to see trends? Starting from a single point, from point to line, from line to surface, how to expand robots into various industries?

Not long ago, we invited Zhang Chaohui, a 21st grade student from the Chaos Innovation Institute and the founder and CEO of Youai Zhihe Robot, to be a guest in the Chaos live broadcast room for the Chaos Innovation Institute's [Chinese Innovative Figures] series of live broadcast columns. He shared "the rise of robots in the next ten years" and what inspiration the "one" thinking has given him for the robot industry.

Sharing guest 丨 Zhang Chaohui, a grade 21 student at Chaos Innovation Institute, founder and CEO of Youai Zhihe Robot

"Wandering Earth2" coincides with the future

In the movie "The Wandering Earth 2", we have about 22 robots used in different scenes.

The relationship with "The Wandering Earth" happened in 2021. At that time, Director Guo Fan happened to see our robot booth at the World Artificial Intelligence Conference. He felt that his vision for 2058 was in line with what UAI is doing now. Things fit together so well. After continued communication with Director Guo Fan, an interesting thought emerged: Will what we are doing today coincide with what we do 30 years from now? We call this idea "pair answers."

You will see our robot appear in various clips in the movie. In fact, if you are not paying special attention to the robot, you will not even feel its existence. Of course, this is actually a success, because it just illustrates the existence of robots in the film without any violating factors. In the words of director Guo Fan, reality is already very science fiction, and many of the robots currently used are consistent with future assumptions.

This is also true. Every product we use in the movie has been shipped in batches in reality. For example, in scenes such as ammunition depots, United Earth Government headquarters, and airports in movies, the wafer handling robots, inspection robots in the energy industry, live working robots, and patrol robots in data rooms are all in real industrial scenes or energy industries. Realize applications and continue to promote the upgrading of related industries.

RobotEvolutionary history, short but rapid

When it comes to robots, everyone generally thinks that such a rapidly developing industry must take a long time to accumulate. But in fact, the development time of the robot industry is very short, lasting less than 100 years. Even the term "robot", the English "robot", is also a very new word, unlike many industries today, such as industry or The service industry has developed for thousands of years.

In 1921, the word "robot" appeared for the first time in a short dramatic novel by Czech writer Karel Capek. In Czech, it actually means a coolie and a slave. 1921 was more than 100 years ago. The robot mentioned at that time was just an imagination, and in the decades from 1921 to 1942, there was not a single product or application in the world for robots.

In 1942, American science fiction writer Isaac Asimov proposed the "Three Laws of Robotics", which was very epoch-making significance at the time, because there were no robots at that time, and he proposed the future entirely in imagination. It is a hypothesis that humans and robots live together. This is very advanced. It is so advanced that even today, when we look at the "Three Laws of Robotics", it is still very applicable to the future.

In 1948, Norbert Wiener proposed cybernetics, which truly brought robots into reality.

In 1954, Unimation Company produced what was then recognized as the first industrial robot. Although it only had a few axes and performed very repetitive movements, it was only nearly seventy years ago, but it has become understandable. The starting point of the robotics industry. Whether it is industrial robots, manipulators, or mobile machinery, they all began to emerge after this starting point.

In 1979, the Stanford Cart came into being. It could analyze and arrange its own action route through cameras, marking the beginning of the basic idea of driverless driving, which was only more than 40 years ago.

Since the 1990s, the robot industry has exploded rapidly.

In 1993, people tried to let robots do things they were unwilling to do themselves. An octagonal machine named Dante sets out to do some dangerous work.

In 1997, the Pathfinder robot was used in the military field to conduct scientific research missions on Mars. This also means that autonomous navigation unmanned operating robots are gradually maturing in the military's outer space exploration process. It took more than 20 years for this theoretical technology, including some cutting-edge applications, to officially enter the civilian stage.

In 2000, robots began to make rapid iterative progress. The Honda ASIMO project was born, and that robot has already lit up the hearts of many people when it first appeared on the stage. Everyone believed that this cross-generational legged robot could gradually mature and replace humans. It is a pity that the Honda ASIMO project was It was officially terminated the year before last, and there was no chance to show off last year. Many robotics companies in China have begun to explore, but so far, there is still a long way to go before commercial implementation.

In 2004, NASA's "Spirit" landed on Mars. This is a very advanced mobile robot application for unmanned operations.

In 2013, China's "Yutu" landed on the moon, proving that China's mobile robots have also become one of the world's leaders in the field of extraterrestrial exploration.

Nowadays, there are endless applications that can make people feel excited. Like Boston Dynamics Robots, since its inception, every video released has made everyone feel that humans will be replaced by robots in advance. But in fact, the very cool robots we have seen on display are still far from being commercially available. Therefore, this year, the warehousing robots released by Boston Dynamics in cooperation with OTTO are much simpler than before, but they also reflect The development trend is oriented towards “people”.

The real commercialization of robots began in 2015, when wheeled robots were widely used in warehousing, industry, restaurants, cleaning and other scenarios. Anti-epidemic robots and medical robots during the epidemic also appeared.

The underlying logic of the development of the robot industry

Like mobile Internet technology 20 years ago, it enters different industries through a basic technology and then helps them achieve productivity improvements and changes. The current mobile robot technology is also produced in the face of such changes. Robots have entered different industries to help realize industrial upgrading of automation and digitalization.

A conclusion can be drawn from this: the explosion of today's robot market is triggered by a segmented application point, and is constantly copied through single functions, causing changes in its original elements.

2017 When I started my business, I was thinking, what are the underlying factors behind the explosive development of the mobile robot industry?

Here is a very interesting thought. When the second industrial revolution came, a large number of people switched from agriculture to industry. A similar situation is now happening in many industries. A large number of workers in the secondary industry have begun to flow to the tertiary industry. The overall labor force has declined, but people have a better life.

This reflects a relatively connected relationship, that is, our productivity is increasing, but the number of labor force is declining, people's needs are increasing, and more iterative demand applications are also increasing. In this development process, there will inevitably be certain gap.

Looking back at the changing trends of the world's population and GDP over the past 100 years, we can find that after 2020, the world's population growth has gradually slowed down, but GDP has achieved a huge increase. The reason for such a contrast must be that there are many factors that can significantly improve The growth efficiency of GDP means that robots will play an increasing role in it.

This process of change is an inevitable and irreversible trend, just like the current low employment rate, but we cannot let people go back to farming for this reason. In fact, it is difficult for us to get more people to return to the factory to do a single task, which is counter-human in itself. Therefore, unmanned transformation will be a long-term demand of all walks of life, and what UAI is doing has the most urgent need in the pan-industrial field.

Youai Zhihe is constantly starting from the bottom and predicting the future of productivity from the nature of the labor force. We divide it into two dimensions: physical strength and mental strength. Physical strength is more based on operating ability, mobility and load capacity. When combined with mechanization, it will become a kind of basic hardware; mental strength is based on more thinking. , perception, language, automatic control of the body, etc. are combined with automation to form an intelligent system. So when we look at the robot's logic, it will be combined with hardware and software.

Robotization in many industries has almost become a relatively inevitable trend. We use our own thinking logic to observe one industry after another, and then by combining it with robots, we find that it is actually a different segmented industry that is gradually evolving. A process that travels through cycles and gradually unfolds.

For example, in 2007-2008, I was very shocked when I saw kiva entering the Amazon warehouse. As a large number of domestic companies began to enter the warehousing and logistics industry in 2015, kiva began to gradually enter a relatively mature stage. This also includes its earliest use of robots to promote automated production in the automotive industry.

Judging from the "market demand in different industry segments gradually crossing the cycle curve chart", we will find that in many industries, the pace of robot replacement is gradually moving forward. The maturity curve of robots coincides with the gradual explosion stage or the gradual expansion stage of market scale.

After 2017, the entire robot industry exploded rapidly, and basically every robot company ushered in rapid growth. In the past six years, UAI Zhihe has doubled its growth every year, and its penetration rate has increased rapidly in different industries.

The founding team and I are committed to researching intelligent mobility because we found that "mobility" has always been a critical link in pan-industrial automation, which requires the combination of material and information flow. Therefore, we always believe that mobile robots should be able to enter scenarios where labor is urgently needed.

After two years of exploration, we have successfully entered the manufacturing and energy and chemical industries. One is to solve the last mile of logistics in the factory, and the other is to automate dangerous operating scenes to ensure personal safety. Both industries use smart mobility to improve production efficiency.

Successful cases of robot implementation scenario application

Uai Zhihe can provide all solutions based on mobile robots. In the early days, our underlying technology was mainly for positioning and navigation algorithms. In the process, we found that when the positioning accuracy of a robot was guaranteed, scheduling became a relatively big problem.

So since 2018, we have invested a lot of energy in the scheduling system and continuously improved the underlying algorithm navigation and scheduling. However, it is difficult for algorithms alone to support relatively large applications. Therefore, in 2017, we quickly developed three relatively standard series of technology carriers. Through the underlying algorithms and technology carriers, we have prepared the underlying layer that can face applications in different industries. drive.

In the past, many mobile robot companies liked to build a platform first, and then provide the platform to different agents to implement the final application.

We are not the same. In 2018, we judged that the industry was in an early stage and many application ecosystems were not yet comprehensive, so we integrated corresponding functions bit by bit, and then installed business systems. In the past few years, we have continued to build on this Filling in the framework eventually forms applications ranging from algorithms to systems, to job scenarios, and to industry coverage.

Industrial logistics is a key application scenario.

Our early involvement was in manufacturing scenario applications. The operation of smart factories urgently requires the intervention of mobile robots. We found that China's manufacturing industry has always been at the bottom of the smile curve, and the industry's status is relatively embarrassing.

In recent years, China's population has been migrating from the secondary industry to the tertiary industry, and labor costs have continued to increase. If you want to support national development through better manufacturing, then data-driven, or building smart factories, may be the solution. very necessary.

To this end, we spent a lot of energy analyzing its pain points. There are major obstacles in the development of material transportation in smart factories, which greatly affects production efficiency and order taking. This is the best entry point for mobile robots to be integrated into factory production.

Then, we have to solve 6 applications, from forklift transfer to warehouse inventory, from cross-floor physical distribution to automated docking of production lines, to machine loading and unloading.

Many people are questioning, isn’t it enough to just make one product and implement links in it?

The manufacturing industry is often changeable, especially the production batches that often undergo major changes, which places high demands on whether robots can quickly adapt to the production line. Therefore, we need to help customers realize the entire material closed loop by continuously enriching product series. The final result is to use 6 product series to complete the last-meter distribution problem, and ultimately realize the full-process automation of smart factories.

The first case is the supply chain serving Apple. This application is implemented in the backplane production scenario of iPhone13 and 14.

It is a supply chain factory, covering an area of more than 2,800 acres, and has 17 factories. We renovated 3 of them. There are more than 200 employees in three factories responsible for transportation. The cumulative distance traveled is about 2,000 kilometers every day, and the daily transportation volume is 70,000 trays. Faced with such a heavy workload, workers would leave one after another every few months because they couldn't bear it.

So we went to the workshop for on-site inspections and repeatedly demonstrated how to use robots to do the manual turnover process. This can reduce some manual work and solve the company's labor difficulties.

After phase after phase of renovation and improvement, the production line circulation method was constantly changed. In the end, approximately 150 machines were used, and the operating results were excellent. The 150 machines transport a distance of more than 2,000 kilometers every day, transporting 70,000 trays, including an ultra-long-distance work task. Combined with the operating results, we pointed out in feedback to customers that the mobile robot not only helped solve high-frequency long-distance transmission tasks, but also discovered some unreasonable problems in production line planning. This example is a good proof that robots can be combined with people and production operations to achieve efficiency improvements.

The second case is applied to the semiconductor industry. After the outbreak of the epidemic in 2020, the semiconductor industry began to experience supply chain disruptions. We spent a lot of time studying how to improve the efficiency of semiconductors, and made a very interesting application to help them quickly complete the flow during the semiconductor production process. Task.

In the past, production and circulation in the semiconductor industry were all carried by people holding small baskets. This was not only inefficient, but also often caused circulation obstruction problems. So we provided customers with 12 mobile robots plus mechanical arms. This set of products can integrate the three functions of hands, eyes and feet to complete up and down movements like humans. This case was very successful. The 12 robots traveled more than 100 kilometers every day and were able to complete the transfer and transportation of more than 2,500 sets and more than 10,000 trays.

The third case is in the PCB industry, covering assembly, chips, and applications on carrier boards. We have deployed 64 robots at a site in Jiujiang to help customers realize logistics transformation in 4 factory areas within 16 kilometers. This has greatly improved efficiency and solved the problem that easily occurs when people pull trolleys. The materials are messy, heavy and difficult to circulate.

The fourth case is in the field of inspection and operation and maintenance. This is another in-depth scenario application. As early as 2017, when the company was first established, it invested a lot of energy in this scenario. At present, we have worked with many energy industry companies, including Huaneng Power Plant, to help them achieve 24/7 uninterrupted operations. The main application scenarios are in thermal power plants, wind power plants, pumped storage power plants and coal mines. This also means that mobile robots have become an infrastructure for smart energy construction.

The core content of the application in the field of inspection and maintenance is to use robots to ensure the stability and continuity of operations and reduce the risk of work.

In 2018, we completed the inspection task of the main engine room of the thermal power plant using only mobile robots and cameras. In 2019, mobile robots have been involved in every aspect of power plant operation. For example, when inspecting coal conveying corridors and power distribution rooms, two staff members can enter to check the situation. Later, the scene application gradually moved from indoor to outdoor, and inspections of booster stations and substations were completed. Basically forming a complete closed loop from inside to outside the venue.

In 2020, we integrated live work into the scene. On the one hand, we conducted inspections and found problems that were directly solved through the operation of mobile robot arms. In the absence of robot applications, accidents in such dangerous operations were relatively frequent. Once mishandled, a high-voltage arc of approximately 6,000 volts would cause personnel to die on the spot. Letting robots carry out operations completely avoids the risk of casualties.

At that time, we told the customer that the worst outcome would be for the arc to break out of the robot. As long as the resistor is released, the robot can be maintained and reused without causing any harm to personnel.

In 2021, we have formed a complete set of solutions. This is the best explanation of starting from the single-point application of a robot and expanding from point to line, from line to surface, into the industry.

Innovation Institute brings me more thinking and inspiration

In addition to the above scenarios, we also apply robots in high-level warehouse inventory, large-scale data centers, and even animal husbandry chicken farms. The application of these scenarios has brought some inspiration: the base generated by the mobile robot can Let everyone consider using intelligent methods to solve problems, and then combine industry needs to form a complete set of application frameworks and logic.

This inspiration is based on our in-depth thinking combined with "one" thinking. This is also the result of my continuous polishing in the study courses when I was studying at the Innovation Institute in 2021, and I thought more about different industries. The insight into the robotics industry at that time was also a basic assumption, that is, we believed that robotics technology would reach a relatively innovative turning point after 2015, its applicability began to improve, and it was possible to apply it to all walks of life.

At the same time, every industry has its unique production characteristics and application characteristics. Just like we have a division of labor, some are teachers, some are lawyers, and some are workers. There are many types of workers. If we divide If robots are regarded as productivity, then robots also have such unique application attributes. Going back to the starting point of thinking, it is what we are doing and whether it has bottom-level penetration.

Based on this kind of thinking, it also proves that mobile robots are gradually becoming a new advanced productivity. In 2019, we began to think more deeply about vertical industries and realized that we must continue to create more industry-competitive mobile robot technology solutions around unique scenarios. With this understanding, we began to deliver implementation plans to more customers and provide timely feedback. When more and more customers use such advanced robot productivity, it will create a positive cognitive cycle.

If we regard industrial robots as new productivity, we first need to understand what kind of productivity can maintain an advantage in the industry and allow the company to form a correct iterative closed loop. Then the answer is self-evident. Only in this Only by being one of the best in the industry and always maintaining the most efficient productivity, or having the largest market share in the target industry, can we accelerate the iteration closed loop faster.

Aware of the core of the problem, the goal will be clearer. As long as UAIZhi cooperates with the selected industry, we will achieve the first market share in this industry as soon as possible. And as long as the entry is detailed and accurate enough, the market is captured and the market share is increased, the product will become increasingly vital and competitive. Therefore, the essence of the rapid growth of the mobile robot industry is to use advanced productivity to make up for the contradictions caused by the evolution of production relations.

After five years, Youai Zhihe has basically become the leader in the industry and realized the first five-year plan. Behind the scenes, we achieve this through our strategic extension to promote the growth flywheel. The basis for realizing all this is that industrial mobile robots are constantly forming new productivity, changing the original production methods, promoting more understanding of industry scenarios, richer career plans, stronger implementation capabilities, and ultimately forming The barriers to segmenting the industry have given us a firm foothold.

In the second step, UAI Zhihe began to work on more “head” cases, a stronger industry reputation, and a larger cooperation ecology, and focused on strengthening brand building in the second five-year plan. For now, we are accelerating this cycle, using lower supply costs, faster display speeds, and lower service costs to form a more industry-competitive infrastructure to promote what we do. development of the industry.

The above is the detailed content of The founder of the robot company in 'The Wandering Earth 2': In the next 10 years, robots will rise!. For more information, please follow other related articles on the PHP Chinese website!

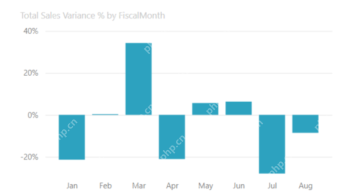

Most Used 10 Power BI Charts - Analytics VidhyaApr 16, 2025 pm 12:05 PM

Most Used 10 Power BI Charts - Analytics VidhyaApr 16, 2025 pm 12:05 PMHarnessing the Power of Data Visualization with Microsoft Power BI Charts In today's data-driven world, effectively communicating complex information to non-technical audiences is crucial. Data visualization bridges this gap, transforming raw data i

Expert Systems in AIApr 16, 2025 pm 12:00 PM

Expert Systems in AIApr 16, 2025 pm 12:00 PMExpert Systems: A Deep Dive into AI's Decision-Making Power Imagine having access to expert advice on anything, from medical diagnoses to financial planning. That's the power of expert systems in artificial intelligence. These systems mimic the pro

Three Of The Best Vibe Coders Break Down This AI Revolution In CodeApr 16, 2025 am 11:58 AM

Three Of The Best Vibe Coders Break Down This AI Revolution In CodeApr 16, 2025 am 11:58 AMFirst of all, it’s apparent that this is happening quickly. Various companies are talking about the proportions of their code that are currently written by AI, and these are increasing at a rapid clip. There’s a lot of job displacement already around

Runway AI's Gen-4: How Can AI Montage Go Beyond AbsurdityApr 16, 2025 am 11:45 AM

Runway AI's Gen-4: How Can AI Montage Go Beyond AbsurdityApr 16, 2025 am 11:45 AMThe film industry, alongside all creative sectors, from digital marketing to social media, stands at a technological crossroad. As artificial intelligence begins to reshape every aspect of visual storytelling and change the landscape of entertainment

How to Enroll for 5 Days ISRO AI Free Courses? - Analytics VidhyaApr 16, 2025 am 11:43 AM

How to Enroll for 5 Days ISRO AI Free Courses? - Analytics VidhyaApr 16, 2025 am 11:43 AMISRO's Free AI/ML Online Course: A Gateway to Geospatial Technology Innovation The Indian Space Research Organisation (ISRO), through its Indian Institute of Remote Sensing (IIRS), is offering a fantastic opportunity for students and professionals to

Local Search Algorithms in AIApr 16, 2025 am 11:40 AM

Local Search Algorithms in AIApr 16, 2025 am 11:40 AMLocal Search Algorithms: A Comprehensive Guide Planning a large-scale event requires efficient workload distribution. When traditional approaches fail, local search algorithms offer a powerful solution. This article explores hill climbing and simul

OpenAI Shifts Focus With GPT-4.1, Prioritizes Coding And Cost EfficiencyApr 16, 2025 am 11:37 AM

OpenAI Shifts Focus With GPT-4.1, Prioritizes Coding And Cost EfficiencyApr 16, 2025 am 11:37 AMThe release includes three distinct models, GPT-4.1, GPT-4.1 mini and GPT-4.1 nano, signaling a move toward task-specific optimizations within the large language model landscape. These models are not immediately replacing user-facing interfaces like

The Prompt: ChatGPT Generates Fake PassportsApr 16, 2025 am 11:35 AM

The Prompt: ChatGPT Generates Fake PassportsApr 16, 2025 am 11:35 AMChip giant Nvidia said on Monday it will start manufacturing AI supercomputers— machines that can process copious amounts of data and run complex algorithms— entirely within the U.S. for the first time. The announcement comes after President Trump si

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

WebStorm Mac version

Useful JavaScript development tools

EditPlus Chinese cracked version

Small size, syntax highlighting, does not support code prompt function

Dreamweaver Mac version

Visual web development tools

Zend Studio 13.0.1

Powerful PHP integrated development environment

SAP NetWeaver Server Adapter for Eclipse

Integrate Eclipse with SAP NetWeaver application server.