Technology peripherals

Technology peripherals AI

AI The synergy of IoT and AI: Unleashing the potential of predictive maintenance

The synergy of IoT and AI: Unleashing the potential of predictive maintenanceThe synergy of IoT and AI: Unleashing the potential of predictive maintenance

The convergence of the Internet of Things (IoT) and artificial intelligence (AI) is creating a transformative synergy that is bound to completely change the industrial landscape. The convergence of these two breakthrough technologies is unlocking the potential of predictive maintenance, a proactive approach that can significantly reduce downtime and increase operational efficiency.

Predictive maintenance, a technology that uses data analytics to predict when equipment failure is likely to occur, has been around for some time. However, the emergence of IoT and artificial intelligence has given it a new dimension. IoT devices have the ability to connect, communicate, and transmit data, providing a wealth of information about the condition of the device. Artificial intelligence, on the other hand, utilizes machine learning algorithms to analyze this data, detect patterns, and predict potential failures before they occur.

The synergy of IoT and artificial intelligence can monitor devices in real time, creating a continuous stream of data that can be analyzed. This is very different from traditional maintenance strategies, which often include regular inspections and reactive repairs. Predictive maintenance, powered by IoT and artificial intelligence, enables businesses to predict equipment failures and schedule maintenance tasks in a timely manner to avoid costly unplanned downtime.

In addition, the combination of IoT and artificial intelligence improves the accuracy of predictive maintenance. By monitoring various parameters such as temperature, pressure, vibration, and humidity, IoT devices can gain a complete understanding of the health of the device. Through its advanced data analysis capabilities, AI is able to sift through large amounts of data, identify subtle patterns, and make accurate predictions. This level of precision is beyond the scope of traditional maintenance methods, which often rely on human judgment and experience.

The integration of IoT and artificial intelligence also facilitates remote monitoring and diagnosis. Central systems can receive data transmitted by IoT devices, analyze it through artificial intelligence algorithms and generate predictive insights. This means maintenance teams can monitor equipment condition and performance anytime, anywhere. This approach can both improve efficiency and reduce the time and cost of on-site inspections.

Additionally, the synergy of IoT and AI provides scalability. As a business expands and operations become more complex, the number of monitoring devices and systems is likely to increase exponentially. IoT and AI can easily scale to handle this increased complexity, making predictive maintenance a viable strategy for businesses of all sizes.

Although IoT and artificial intelligence have great potential for predictive maintenance, there are some challenges. Since IoT devices are vulnerable to cyberattacks, data security and privacy become an important issue. Furthermore, implementation of these technologies requires significant investments in infrastructure and skills development.

Despite some challenges, the benefits of predictive maintenance driven by the collaboration of IoT and artificial intelligence are clearly more prominent. This approach can significantly improve operational efficiency and profitability by enabling businesses to predict equipment failures, optimize maintenance schedules and reduce downtime. Therefore, integrating IoT and artificial intelligence is not only a technological advancement, but also a strategic task for enterprises to remain competitive in the digital age.

The above is the detailed content of The synergy of IoT and AI: Unleashing the potential of predictive maintenance. For more information, please follow other related articles on the PHP Chinese website!

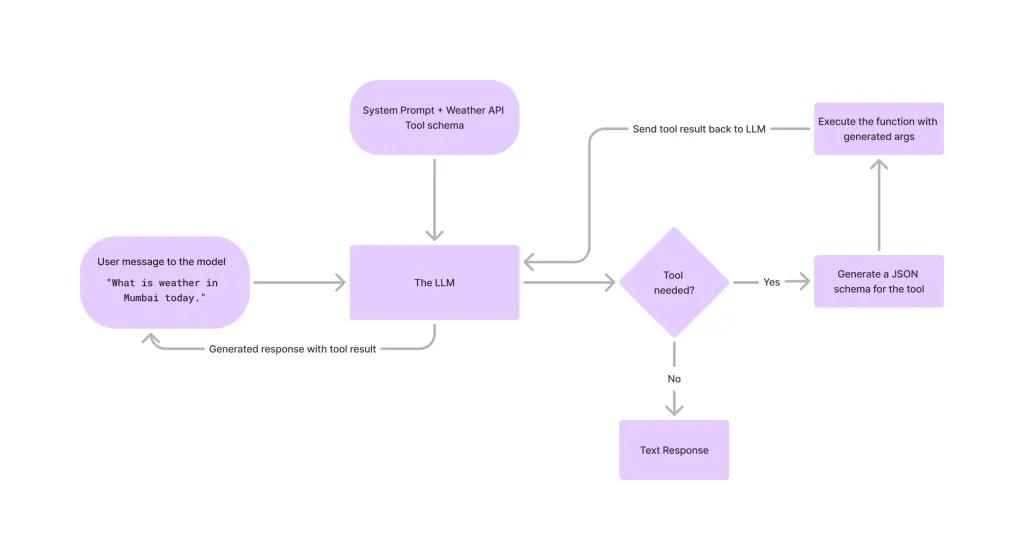

Tool Calling in LLMsApr 14, 2025 am 11:28 AM

Tool Calling in LLMsApr 14, 2025 am 11:28 AMLarge language models (LLMs) have surged in popularity, with the tool-calling feature dramatically expanding their capabilities beyond simple text generation. Now, LLMs can handle complex automation tasks such as dynamic UI creation and autonomous a

How ADHD Games, Health Tools & AI Chatbots Are Transforming Global HealthApr 14, 2025 am 11:27 AM

How ADHD Games, Health Tools & AI Chatbots Are Transforming Global HealthApr 14, 2025 am 11:27 AMCan a video game ease anxiety, build focus, or support a child with ADHD? As healthcare challenges surge globally — especially among youth — innovators are turning to an unlikely tool: video games. Now one of the world’s largest entertainment indus

UN Input On AI: Winners, Losers, And OpportunitiesApr 14, 2025 am 11:25 AM

UN Input On AI: Winners, Losers, And OpportunitiesApr 14, 2025 am 11:25 AM“History has shown that while technological progress drives economic growth, it does not on its own ensure equitable income distribution or promote inclusive human development,” writes Rebeca Grynspan, Secretary-General of UNCTAD, in the preamble.

Learning Negotiation Skills Via Generative AIApr 14, 2025 am 11:23 AM

Learning Negotiation Skills Via Generative AIApr 14, 2025 am 11:23 AMEasy-peasy, use generative AI as your negotiation tutor and sparring partner. Let’s talk about it. This analysis of an innovative AI breakthrough is part of my ongoing Forbes column coverage on the latest in AI, including identifying and explaining

TED Reveals From OpenAI, Google, Meta Heads To Court, Selfie With MyselfApr 14, 2025 am 11:22 AM

TED Reveals From OpenAI, Google, Meta Heads To Court, Selfie With MyselfApr 14, 2025 am 11:22 AMThe TED2025 Conference, held in Vancouver, wrapped its 36th edition yesterday, April 11. It featured 80 speakers from more than 60 countries, including Sam Altman, Eric Schmidt, and Palmer Luckey. TED’s theme, “humanity reimagined,” was tailor made

Joseph Stiglitz Warns Of The Looming Inequality Amid AI Monopoly PowerApr 14, 2025 am 11:21 AM

Joseph Stiglitz Warns Of The Looming Inequality Amid AI Monopoly PowerApr 14, 2025 am 11:21 AMJoseph Stiglitz is renowned economist and recipient of the Nobel Prize in Economics in 2001. Stiglitz posits that AI can worsen existing inequalities and consolidated power in the hands of a few dominant corporations, ultimately undermining economic

What is Graph Database?Apr 14, 2025 am 11:19 AM

What is Graph Database?Apr 14, 2025 am 11:19 AMGraph Databases: Revolutionizing Data Management Through Relationships As data expands and its characteristics evolve across various fields, graph databases are emerging as transformative solutions for managing interconnected data. Unlike traditional

LLM Routing: Strategies, Techniques, and Python ImplementationApr 14, 2025 am 11:14 AM

LLM Routing: Strategies, Techniques, and Python ImplementationApr 14, 2025 am 11:14 AMLarge Language Model (LLM) Routing: Optimizing Performance Through Intelligent Task Distribution The rapidly evolving landscape of LLMs presents a diverse range of models, each with unique strengths and weaknesses. Some excel at creative content gen

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Zend Studio 13.0.1

Powerful PHP integrated development environment

PhpStorm Mac version

The latest (2018.2.1) professional PHP integrated development tool

WebStorm Mac version

Useful JavaScript development tools

MinGW - Minimalist GNU for Windows

This project is in the process of being migrated to osdn.net/projects/mingw, you can continue to follow us there. MinGW: A native Windows port of the GNU Compiler Collection (GCC), freely distributable import libraries and header files for building native Windows applications; includes extensions to the MSVC runtime to support C99 functionality. All MinGW software can run on 64-bit Windows platforms.

VSCode Windows 64-bit Download

A free and powerful IDE editor launched by Microsoft