Operation and Maintenance

Operation and Maintenance Safety

Safety Why should I spend the time before retirement struggling with the operation and maintenance knowledge automation system?

Why should I spend the time before retirement struggling with the operation and maintenance knowledge automation system?My team has been doing system optimization since 2003. At the invitation of HP SERVICE, I joined their Haier system optimization team in 2003 and was responsible for the optimization of Oracle database. This was my first time to participate in the optimization of a large-scale system. Even at that time, I didn't know where to start optimizing a large-scale after-sales service system. I went to Qingdao to participate in this optimization project with a book by Levi's. Through this project, I gained a preliminary understanding of the optimization of Oracle databases. Later, I helped HP complete the performance evaluation of the CAF platform used in Huawei's SCM system, and recommended to the decision-makers to stop the project in time to avoid greater waste of funds, because the project could no longer be optimized. Later, HP adopted my suggestion and closed the project based on the CAF platform. Huawei also re-selected Oracle EBS as the basis of the SCM system and ERP system. Since then, our team has grown in size, done more and more optimization projects, and trained a group of experts in system optimization.

In 2011, we began to help the State Grid with system optimization. Under the leadership of experts, the first few projects achieved particularly good results. The customer wanted us to expand the scope of optimization and developed a large-scale optimization project that required nearly a hundred DBAs. We recruited dozens of DBAs from many partners to participate in this project. In order to ensure the quality of the project, we conducted multiple centralized trainings for the entire team. However, in the end, the results of this project were very unsatisfactory. The main reason is that the abilities of DBAs are uneven, and most of them have not participated in large-scale optimization projects. Since that project, I have also been thinking about the problems of the traditional operation and maintenance model that relies on people and experts, hoping to find a way to make the experience of experts play a greater role. This is my original intention to develop D-SMART, an operation and maintenance knowledge automation system. In order to build a knowledge automation system, the degree of digitization in Yunzhong must be improved. However, the degree of digitalization of IT operations and maintenance in traditional industries is very low. There are several main reasons for this.

Limited resources: Many companies may not have enough resources to invest in R&D and implementation of intelligent operation and maintenance systems, or may think that investing resources in other aspects is more rewarding.

Cultural factors: Some businesses may prefer to rely on human experience rather than automated systems, perhaps because they lack trust in automated systems, or they may believe that expert judgment is more reliable than machines in an emergency.

Technical limitations: Some companies may lack the necessary technical infrastructure to support intelligent operation and maintenance systems, which may require higher costs to upgrade equipment and systems.

Lack of awareness: Some enterprises may not be aware of the potential advantages of digital operations, or may not have enough knowledge and understanding of how to implement digital operations.

Although traditional industries have various cognitive deficiencies in digital operation and maintenance, with the development of technology and the increasing importance of digitalization, intelligent operation and maintenance will become a trend in future information system operation and maintenance, and also An inevitable direction.

Reflecting on our work experience in system optimization and operation and maintenance over the years, inexperienced technical personnel are an important factor leading to poor optimization results. Optimization work requires professional knowledge and skills rather than relying solely on experience. More systematic training may be needed to ensure that all personnel involved in optimization efforts have the necessary skills and knowledge. In addition, the effect of optimization work is also affected by multiple factors, such as system design, data quality and optimization work process.

With the continuous development of technology, many intelligent algorithms and methods are now available, which can greatly improve operation and maintenance efficiency and reduce human errors. Operation and maintenance knowledge automation tools can provide intelligent analysis and automated operations to help DBAs better manage and optimize the system. If the enterprise has sufficient resources, it can consider introducing these tools and systems to improve operation and maintenance efficiency. The "operation and maintenance knowledge automation system" combines big data analysis, artificial intelligence and other technologies, as well as expert experience and work accumulation, to build a comprehensive operation and maintenance knowledge system, which can help improve the efficiency and quality of operation and maintenance work. Through monitoring indicator systems, health models, operation and maintenance knowledge maps, anomaly detection algorithms and other technologies, the "operation and maintenance knowledge automation system" can automatically analyze and solve system performance problems, and at the same time provide intelligent optimization suggestions and decision-making support for Provides strong support for the enterprise's operation and maintenance work.

In fact, the most important purpose of D-SMART system development is to summarize our team’s more than 20 years of experience in IT operation and maintenance and system optimization, so that the experts in the team can accumulate experience over the years. experience into a digital knowledge base that can be automated. And through continuous iteration of the knowledge base, operation and maintenance knowledge can be continuously accumulated and accumulated in the platform, thereby continuously improving the ability of automated analysis.

The research and development of this system does not only rely on the R&D team. The research and development of knowledge tools is completely completed by the DBA without the help of ordinary operation and maintenance personnel. This is because ordinary R&D personnel do not understand IT operations, databases, and performance optimization. Only DBAs who have done operation and maintenance work can more accurately turn experts' ideas into automated tools.

The starting point of the D-SMART system is the indicator system. I think indicators are part of expert experience, and they are a very important part. Only indicators recognized by experts can be fully interpreted. At present, many database monitoring software provide many indicators that operation and maintenance personnel cannot correctly interpret. Even if these indicators are abnormal, they may not be discovered. In other words, if abnormal indicators are discovered, they cannot sense where the problem is in the system. The indicator data sorted out by experts are single and can be interpreted by experts, so each indicator will be marked by experts and given a specific label.

The second step of D-SMART is to complete the accurate collection of indicators. Accurate collection of data for each indicator is very critical for an intelligent operation and maintenance system. It is critical to ensure that every data accurately reflects the true state of the database. After a lot of data is collected, it needs to be processed before it can be turned into usable indicators. These processing algorithms also reflect the experience of experts. Through this step, the D-SMART system continuously obtains a digital model of the database's operating status.

The third step is to conduct automated modeling analysis on the collected indicators and log data. We use the health model to determine whether the running status of the database is normal and whether there are risks; we use the performance model to understand the overall performance status of the database; we use the load model to understand the current load situation of the database; we use the fault model to discover possible hidden dangers in the database and provide timely alarms.

The fourth step is to use the collected data to automatically complete various inspection tasks. For example, during daily inspection, the system will automatically analyze the data collected the previous day at midnight every day, discover the risks and hidden dangers, and generate a daily inspection report. Every month or every week, you can customize tasks to automatically analyze the recently collected data and generate inspection reports. This kind of inspection can analyze comprehensive data and has richer data than the traditional method of manual data collection and manual analysis. Algorithms that automate analysis are also more efficient.

Using this data, you can also do a lot of valuable analysis work, such as capacity prediction, performance optimization, special audits, etc. At the same time, using the standardized indicator system, we can also build digital communication between first-line operations and second- and third-line operations. Through a complete indicator set, we can provide third-line operations with a panoramic view of database operation as comprehensively as possible, truly eliminating the need for On site, experts can know everything about the world.

A while ago, my mother, who is over 80 years old, made sure to celebrate my birthday. She has been running around for many years and has not celebrated a birthday for more than ten years. When I put the candles, I realized that I was already 54 years old after my birthday, and there was not much time left before retirement. I want to digitize the experience accumulated over the years as much as possible while I can still do something now, so that I can keep it, so that there will be no regrets.

The above is the detailed content of Why should I spend the time before retirement struggling with the operation and maintenance knowledge automation system?. For more information, please follow other related articles on the PHP Chinese website!

Uber部署2000机器人大军,力争2026年在美实现自动送餐Jun 03, 2023 pm 12:09 PM

Uber部署2000机器人大军,力争2026年在美实现自动送餐Jun 03, 2023 pm 12:09 PMDoNews6月2日消息,外送巨头UberEats与ServeRobotics近日正式宣布自2026年起,要在美国各主要城市推出机器人送餐服务。据IT之家援引外媒报道,ServeRobotics表示,这款配备4个轮子的机器人使用AI技术进行路径规划,其续航约为40公里,可运载重达23公斤的商品。此外,该公司的机器人每天可负责数十张订单的配送。Uber表示,消费者通过UberEats下单,会提供由机器人送餐的选项。机器人送餐到指定地点后,顾客需要输入密码才能取餐,以此来保障顾客的食品安全送达。目前

十个值得推荐的自动化和编排工具Apr 14, 2023 pm 02:40 PM

十个值得推荐的自动化和编排工具Apr 14, 2023 pm 02:40 PM自动化和编排网络工具可以比管理人员更快、更准确地执行任务。IT流程自动化本身就是卖点:自动化任务不仅比工作人员执行重复性活动更便宜,而且更高效、更可预测。虽然自动化和编排工具可以与企业员工一起开发自动化工具,但这可能具有挑战性,如果最终需要大规模采用自动化技术的话,可能需要使用商业软件工具。一些任务比其他任务更容易实现自动化,例如管理IT系统、配置物理机和虚拟机、管理服务器配置、识别策略偏差,许多IT系统现在都具有一些功能,这些功能使其更容易在不寻求采用商业平台的情况下实现自动化。此外,在过去的

未来的工作:适应自动化和人工智能Jun 07, 2023 pm 07:42 PM

未来的工作:适应自动化和人工智能Jun 07, 2023 pm 07:42 PM自动化和人工智能(AI)的快速发展正在重塑劳动力队伍,并对未来的工作提出质疑。企业需要具备适当技能的员工来开发、管理和维护自动化设备和数字流程,并完成机器无法完成的工作。再培训可以帮助留守员工找到新的职业。在竞争激烈的就业市场中,员工需要学习新技能,这是至关重要的。本文探讨了自动化和人工智能对就业的影响、不断变化的就业市场所需的技能,以及适应性和终身学习的重要性。自动化的兴起:改变行业和工作角色自动化技术正在彻底改变从制造和物流到客户服务和医疗保健的行业。机器人、机器学习算法和人工智能系统越来越

如何开始使用Python中的NoseApr 11, 2023 pm 09:31 PM

如何开始使用Python中的NoseApr 11, 2023 pm 09:31 PM译者 | 李睿审校 | 孙淑娟在这个Python Nose教程中,将深入研究Nose框架。Nose是一个测试自动化框架,它扩展了unittest,并进一步利用Nose来执行Selenium测试自动化。许多开发人员在Selenium测试自动化中面临的一个挑战是如何选择正确的测试框架,以帮助他们以最少(或不需要)的样板代码完成自动化测试。大多数人都会遇到测试代码,并不得不编写大量代码来执行简单的测试。选择正确的测试自动化框架可以显著地简化开发人员处理测试代码的工作。可以利用框架功能编写测试,以最少

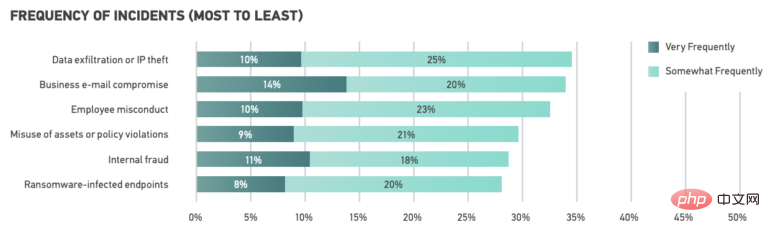

人工取证不堪重负!自动化DFIR(数字取证和事件响应)才是未来Apr 28, 2023 pm 02:49 PM

人工取证不堪重负!自动化DFIR(数字取证和事件响应)才是未来Apr 28, 2023 pm 02:49 PM数十年来,数字取证工作在司法侦查的不同分支中不断发展,已成为全球执法活动中非常重要的组成部分。与此同时,由于互联网和全球化的发展,犯罪形式多样化,执法人员也需要通过自动化的数字取证工具,才能获取关键的数字证据,将不法分子送入监狱。日前,Magnetforensics研究团队最新发布了《企业数字取证和事件调查(DFIR)应用现状》研究报告。报告研究认为,数字取证市场目前发生了很大变化,可以用两个词来概括:速度和准确率。如何尽快将违法证据提交给调查人员是将网络犯罪分子绳之以法的关键。然而,这并不容易

人工智能和物联网在供应链管理中的应用Apr 10, 2023 pm 04:31 PM

人工智能和物联网在供应链管理中的应用Apr 10, 2023 pm 04:31 PM在疫情期间,供应链部门遭遇了劳动力短缺、需求增加和过度订购。管理人员自然会寻找技术解决方案,以提高生产率并使分销过程自动化。31.52%的供应链高管采用机器人技术,实现高效配送、快速分拣和人工辅助。疫情后,随着物流业逐步反弹,自动化在小规模工业中激增,每年生产5000 - 6000个机器人,部署在配送过程的各个阶段。因此,从2023年到2028年,印度物流自动化市场预计将以16.2%的复合年增长率增长。供应链管理中的人工智能和物联网驱动的机器人仓库和物流中心充斥着耗时耗力的日常工作和危险任务。尽

RPA实施路线图的长远考虑Apr 10, 2023 pm 09:01 PM

RPA实施路线图的长远考虑Apr 10, 2023 pm 09:01 PM很多企业投资机器人流程自动化(RPA)的主要原因包括精简内部的业务流程自动化计划,解决流程效率低下和瓶颈问题。自动化仍然是增长最快的企业软件类别之一,研究机构Gartner公司在最近发布的一份报告中预计,全球RPA软件收入将比去年增长近20%。虽然RPA解决方案传统上专注于通过屏幕抓取自动化任务,但如今的现代RPA解决方案专注于API优先的流程自动化方法。与此同时,RPA供应商正在不断增强他们的API集成能力,为客户提供基于用户界面的屏幕抓取和API优先的集成能力。Gartner公司高级市场研究

低代码自动化将如何改变银行业Apr 09, 2023 am 11:21 AM

低代码自动化将如何改变银行业Apr 09, 2023 am 11:21 AM在基本的经常账户功能方面,银行几乎没有什么区别,因此公司需要为客户提供更多的服务。对于传统商业银行来说,这一点尤其重要,因为它们面临着来自更新颖、更灵活的基于应用程序的挑战者银行和其他金融科技竞争对手的威胁。现任者可能会被遗留系统所困扰,但他们确实拥有关于客户偏好的经验和数据,可以利用这些经验和数据为自己带来好处。公司需要新产品,新方法和新想法来吸引和留住客户。但如果他们想要保持竞争力,他们还需要快速的交付它们,并能够根据不断变化的业务和监管需求来更改它们。这就带来了自动化——31%的金融服务高

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Dreamweaver CS6

Visual web development tools

WebStorm Mac version

Useful JavaScript development tools

Zend Studio 13.0.1

Powerful PHP integrated development environment

SAP NetWeaver Server Adapter for Eclipse

Integrate Eclipse with SAP NetWeaver application server.

Safe Exam Browser

Safe Exam Browser is a secure browser environment for taking online exams securely. This software turns any computer into a secure workstation. It controls access to any utility and prevents students from using unauthorized resources.