Technology peripherals

Technology peripherals AI

AI SIASUN brings multiple categories of robot products to the Tianjin exhibition area of the 7th World Intelligence Conference

SIASUN brings multiple categories of robot products to the Tianjin exhibition area of the 7th World Intelligence ConferenceSIASUN brings multiple categories of robot products to the Tianjin exhibition area of the 7th World Intelligence Conference

From May 18th to 21st, the 7th World Intelligence Conference was held grandly at the National Convention and Exhibition Center (Tianjin). This year's World Intelligence Conference has the theme of "Smart mobility drives the future", adhering to the idea of "high-end, international, professional and market-oriented" conferences, focusing on empowering economic and social development with smart technology, and gathering talents from all over the world. Plan for a smart future, gather smart achievements, achieve win-win sharing, and comprehensively create a new window to showcase Smart Tianjin and Digital China.

▲ SIASUN brings intelligent robot products and solutions to the Tianjin exhibition area of the World Intelligence Conference

SIASUN will bring advanced and easy-to-use intelligent products and solutions such as arc intelligent welding robots, industrial robot teaching-free welding systems, collaborative robot car pedal pressure testing systems, etc. to the Tianjin exhibition area of the conference!

▲ At the conference site, many delegations visited SIASUN booth

▲ The audience enthusiastically visited and experienced

Xinsong Fire Arc Intelligent Welding Robot

SIASUN arc intelligent welding robot is specially developed for high-demand arc welding applications. The control system and robot body are independently developed and designed by SIASUN, which can meet the requirements of high precision, high speed and high stability under demanding production rhythms. Operation. The hollow arch design of the robot reduces workpiece interference, optimizes the envelope space, improves operating flexibility, and enables interference-free high-density layout. The wire feeder is integrated into the robot body, and the integrated wiring tube is scientifically designed. It can be seated or hoisted, and is capable of operating in small turning radius and narrow areas.

Industrial robot teaching-free welding system

Currently, the mainstream robot welding systems in the market still use manual teaching or offline programming methods, which are more suitable for single-product and large-volume welding, but are incompetent for multi-variety and small-batch welding tasks.

Xinsong industrial robot teaching-free welding system automatically identifies workpieces through visual guidance, intelligent welding control software performs path planning on weld information, and uses point laser technology to specifically identify welding points, thereby achieving fully automatic welding . On the horizontal plane, the entire workpiece can be rotated at any angle, truly realizing teaching-free welding of arbitrarily placed structural parts. This system is highly scalable and can integrate cutting-edge technologies such as welding expert systems and deep learning of welding postures and paths to achieve intelligent and efficient displacement collaborative welding of complex structural parts. It is widely used in many industries such as petrochemical, shipbuilding, and machinery manufacturing.

Collaborative robot car pedal pressure testing system

The automobile pedal pressure test is mainly used to detect the return force at each position of the pedal stroke. This application uses a multi-collaborative robot equipped with an end force control sensor. The robot presses and outputs the time and end speed versus time relationship curves. The force control sensor collects the pedal return pressure and outputs the force versus time relationship curve. Through The software calculates and obtains the relationship curve between stroke and time, and finally the relationship curve between force and stroke. By calculating the data and the extreme value of the return force, and comparing it with the required return force curve, it is finally determined whether the pedal return force meets the return force requirements.

Manufacturing is the foundation of a country and a strong country. This conference focuses on the important mission of revitalizing the real economy and developing advanced manufacturing. SIASUN will fully unleash the enabling role of robots and artificial intelligence technology, fully promote the high-end, intelligent, and green development of my country's manufacturing industry, and help global partners share the dividends of the smart economy! From May 18th to 21st, SIASUN is looking forward to your visit at the 7th World Intelligence Conference!

The 7th World Intelligence Conference

Time: May 18-21, 2023

Location: Jinnan District, Tianjin·National Convention and Exhibition Center

Booth: Tianjin Exhibition Area

The above is the detailed content of SIASUN brings multiple categories of robot products to the Tianjin exhibition area of the 7th World Intelligence Conference. For more information, please follow other related articles on the PHP Chinese website!

The AI Skills Gap Is Slowing Down Supply ChainsApr 26, 2025 am 11:13 AM

The AI Skills Gap Is Slowing Down Supply ChainsApr 26, 2025 am 11:13 AMThe term "AI-ready workforce" is frequently used, but what does it truly mean in the supply chain industry? According to Abe Eshkenazi, CEO of the Association for Supply Chain Management (ASCM), it signifies professionals capable of critic

How One Company Is Quietly Working To Transform AI ForeverApr 26, 2025 am 11:12 AM

How One Company Is Quietly Working To Transform AI ForeverApr 26, 2025 am 11:12 AMThe decentralized AI revolution is quietly gaining momentum. This Friday in Austin, Texas, the Bittensor Endgame Summit marks a pivotal moment, transitioning decentralized AI (DeAI) from theory to practical application. Unlike the glitzy commercial

Nvidia Releases NeMo Microservices To Streamline AI Agent DevelopmentApr 26, 2025 am 11:11 AM

Nvidia Releases NeMo Microservices To Streamline AI Agent DevelopmentApr 26, 2025 am 11:11 AMEnterprise AI faces data integration challenges The application of enterprise AI faces a major challenge: building systems that can maintain accuracy and practicality by continuously learning business data. NeMo microservices solve this problem by creating what Nvidia describes as "data flywheel", allowing AI systems to remain relevant through continuous exposure to enterprise information and user interaction. This newly launched toolkit contains five key microservices: NeMo Customizer handles fine-tuning of large language models with higher training throughput. NeMo Evaluator provides simplified evaluation of AI models for custom benchmarks. NeMo Guardrails implements security controls to maintain compliance and appropriateness

AI Paints A New Picture For The Future Of Art And DesignApr 26, 2025 am 11:10 AM

AI Paints A New Picture For The Future Of Art And DesignApr 26, 2025 am 11:10 AMAI: The Future of Art and Design Artificial intelligence (AI) is changing the field of art and design in unprecedented ways, and its impact is no longer limited to amateurs, but more profoundly affecting professionals. Artwork and design schemes generated by AI are rapidly replacing traditional material images and designers in many transactional design activities such as advertising, social media image generation and web design. However, professional artists and designers also find the practical value of AI. They use AI as an auxiliary tool to explore new aesthetic possibilities, blend different styles, and create novel visual effects. AI helps artists and designers automate repetitive tasks, propose different design elements and provide creative input. AI supports style transfer, which is to apply a style of image

How Zoom Is Revolutionizing Work With Agentic AI: From Meetings To MilestonesApr 26, 2025 am 11:09 AM

How Zoom Is Revolutionizing Work With Agentic AI: From Meetings To MilestonesApr 26, 2025 am 11:09 AMZoom, initially known for its video conferencing platform, is leading a workplace revolution with its innovative use of agentic AI. A recent conversation with Zoom's CTO, XD Huang, revealed the company's ambitious vision. Defining Agentic AI Huang d

The Existential Threat To UniversitiesApr 26, 2025 am 11:08 AM

The Existential Threat To UniversitiesApr 26, 2025 am 11:08 AMWill AI revolutionize education? This question is prompting serious reflection among educators and stakeholders. The integration of AI into education presents both opportunities and challenges. As Matthew Lynch of The Tech Edvocate notes, universit

The Prototype: American Scientists Are Looking For Jobs AbroadApr 26, 2025 am 11:07 AM

The Prototype: American Scientists Are Looking For Jobs AbroadApr 26, 2025 am 11:07 AMThe development of scientific research and technology in the United States may face challenges, perhaps due to budget cuts. According to Nature, the number of American scientists applying for overseas jobs increased by 32% from January to March 2025 compared with the same period in 2024. A previous poll showed that 75% of the researchers surveyed were considering searching for jobs in Europe and Canada. Hundreds of NIH and NSF grants have been terminated in the past few months, with NIH’s new grants down by about $2.3 billion this year, a drop of nearly one-third. The leaked budget proposal shows that the Trump administration is considering sharply cutting budgets for scientific institutions, with a possible reduction of up to 50%. The turmoil in the field of basic research has also affected one of the major advantages of the United States: attracting overseas talents. 35

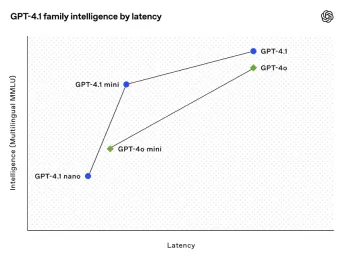

All About Open AI's Latest GPT 4.1 Family - Analytics VidhyaApr 26, 2025 am 10:19 AM

All About Open AI's Latest GPT 4.1 Family - Analytics VidhyaApr 26, 2025 am 10:19 AMOpenAI unveils the powerful GPT-4.1 series: a family of three advanced language models designed for real-world applications. This significant leap forward offers faster response times, enhanced comprehension, and drastically reduced costs compared t

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Atom editor mac version download

The most popular open source editor

MantisBT

Mantis is an easy-to-deploy web-based defect tracking tool designed to aid in product defect tracking. It requires PHP, MySQL and a web server. Check out our demo and hosting services.

DVWA

Damn Vulnerable Web App (DVWA) is a PHP/MySQL web application that is very vulnerable. Its main goals are to be an aid for security professionals to test their skills and tools in a legal environment, to help web developers better understand the process of securing web applications, and to help teachers/students teach/learn in a classroom environment Web application security. The goal of DVWA is to practice some of the most common web vulnerabilities through a simple and straightforward interface, with varying degrees of difficulty. Please note that this software

WebStorm Mac version

Useful JavaScript development tools

SAP NetWeaver Server Adapter for Eclipse

Integrate Eclipse with SAP NetWeaver application server.