Why predictive maintenance makes sense for healthy buildings

Data-driven operational strategies can reduce costs, increase productivity, and support a better overall environment.

#The rise of Internet of Things (IoT) technology has added a new dimension to maintenance planning. Data from IoT devices can provide facilities managers with insights to effectively operate and maintain their properties, and when combined with a smart building platform that provides analytics, can identify and resolve issues more effectively.

Analytics is more than just reactive device alerts or reports. They are based on relevant data that is clearly presented in an easy-to-understand format that explains the problem, when it occurred, its duration, the status of relevant operating conditions, and even the cost impact. Analysis shows how the built system works in reality, rather than relying on operational assumptions.

Smart building system operators use predictive or data-driven maintenance strategies combined with analytics to ensure efficient maintenance practices.

Reactive, Preventive, Better yet Predictive

Historically, construction personnel would correct problems as they occurred, otherwise known as reactive, corrective, or run-to- Breakdown maintenance. The staff will only repair items if they are damaged, and leave them alone if they are not damaged.

This strategy can be costly. According to the Specialty Retail Store Maintenance Association's (now ConnexFM) 2012 HVAC Benchmark Report, reactive service calls after equipment failure cost on average three times more than proactive calls, approximately $400 more per call.

In the early 20th century, with the advent of mass production of automobiles, preventive or planned maintenance was introduced. This has prompted other industries to develop their own practices. Planned maintenance relies heavily on guessing how much equipment time or usage time must be spent before maintenance is due based on the manufacturer's specifications. This strategy is also not feasible or cost-effective to predict every failure, so its use is limited to runtime or interval-based problems.

While preventive maintenance can reduce reactive costs, it can also increase standard operating costs by initiating unnecessary inspections or repairs. Preventive maintenance, based on an estimate of when equipment is likely to need repairs, neither predicts equipment degradation based on actual conditions and usage nor prevents equipment failure.

On the other hand, predictive maintenance, also known as data-driven or condition-based maintenance, injects intelligence into building maintenance by using objective data to identify issues that may affect future equipment performance. It avoids many of the costly issues associated with reactive maintenance while allowing stakeholders to develop strategies for monitoring and maintaining equipment, comfort and cost.

Advantages of Predictive Maintenance

System maintenance should be performed when specific indicators show signs of degraded performance, increased energy consumption, or impending failure. Predictive maintenance can identify problems before anyone notices, and before repair and operating costs rise. It pinpoints the root cause of a problem, simplifies diagnosis and repair, and reduces second visits. This strategy can also identify design issues such as incorrect sequence of operations, undersized ducts or pipes, mismatched components, or improper zoning.

Predictive maintenance helps determine the exact nature of the problem and assists in dispatching the right technician with the right information and parts. Other advantages of predictive maintenance include:

- Reduced truck rolls.

- Reduce the total time to solve the problem.

- Improve first-time repair rate.

- Reduce ongoing debugging.

- Reduce overall maintenance costs.

- Reduce the risk of major failures.

- Add direct fixes as problems are discovered at an early stage.

- Reduce downtime, delays and interruptions.

- Provide consistent comfort and environment for end users.

- Allocate maintenance budget and resources more accurately.

- Better equipment performance and longer equipment service life.

- Reduce maintenance costs.

- Easier to comply with regulatory requirements.

- Improve energy efficiency.

Preventive maintenance programs require adequate and reliable building data. The best way to obtain building data is through IoT sensors.

Enter IoT Sensors

IoT sensors are available in many shapes and sizes and can be installed on a variety of systems during or after initial installation. These systems include HVAC, energy, lighting, access control, irrigation and occupancy.

The smart building management platform uses machine learning (ML) algorithms to analyze equipment and IoT data to identify performance trends, enabling targeted maintenance and early intervention to prevent major problems. However, a macro approach is needed to combine large amounts of data ingested from different environments and conditions to create a big picture to predict failure probabilities and possible improvements in operational performance.

All buildings are unique and many problems cannot be discovered during regular maintenance. Conditions detected through analytics and ML provide suppliers with a comprehensive plan to repair and maintain equipment showing signs of failure, wear and reduced efficiency. This ultimately reduces the impact of equipment damage, including cost and disruption to facility managers and occupants.

The real difference between predictive maintenance and preventive maintenance is that the former uses a real-time data-driven approach specific to the actual condition of the equipment. This means manual inspections, replacements and repairs are only done when necessary. Predictive maintenance is based on data predicting problems so that measures can be taken to prevent equipment failure. Additionally, as machine learning-driven smart building management platforms learn more about buildings and their uses, they will produce increasingly accurate and specific predictions.

Predictive maintenance goes beyond building systems. For example, accurate occupancy forecasting enables operators to predict the cleaning and sanitation needs of each area and allocate resources accordingly.

About Occupancy

The proliferation of hybrid working means workplaces must find new ways to meet changing demands and remain efficient and safe. Occupancy forecasts are a powerful tool for predictive maintenance. Smart building management platforms can use data collected by sensors to predict future occupancy. This information helps improve the efficiency of office space and ensures that building automation strategies support a healthy indoor environment, even if occupancy rates vary widely.

Through occupancy prediction, smart building management platforms can:

- Automatically adjust HVAC settings to keep comfort and air quality at an appropriate level to accommodate the number of people.

- Automatically adjust lighting to meet the needs of the occupants.

- Eliminate unnecessary heating, cooling, ventilation and lighting in unused areas.

- Identify areas for improvement.

- Provide information to improve space utilization.

Occupancy forecasts can provide valuable data for workplace applications where employees can reserve cubicles, conference rooms, desks and offices. These forecasts are similar to how hotels use daily, monthly, quarterly and annual occupancy models to allocate rooms based on their forecasts.

Understanding actual and planned occupancy allows buildings to run more efficiently. For example, lights can be turned on only when needed, and HVAC systems can be shut down when occupants need to regulate the air. Having historical data based on actual occupancy scenarios allows for appropriate forecasting.

Predictive maintenance is the future

Analytics and machine learning are the future of building maintenance. Data-driven predictive maintenance programs can revolutionize the way buildings operate by replacing irrelevant routine inspections and preventing equipment degradation. It allows for more proactive monitoring of system health, opportunities to optimize performance, and overall robust decision-making. In addition, Key prioritizes the impact of maintenance on performance, energy and comfort.

Integrating predictive maintenance programs requires an investment in a smart building platform. The mobile-first platform features cutting-edge fault detection and diagnostics, machine learning, IoT devices, apps and user-friendly interfaces, ensuring teams can take building maintenance to the next level.

Any analytics or smart building platform is only as good as the data it receives. The more data collected from IoT sensors and integrated systems, the better the results. Designing and implementing specific solutions requires deep domain expertise in open communication protocols, data integration and system interoperability. Individual project needs must be assessed with partners who understand the complexities of smart buildings to gain the full benefits of a data-driven, future-proof solution with a practical approach to predictive maintenance.

The above is the detailed content of Why predictive maintenance makes sense for healthy buildings. For more information, please follow other related articles on the PHP Chinese website!

A Comprehensive Guide to Selenium with PythonApr 15, 2025 am 09:57 AM

A Comprehensive Guide to Selenium with PythonApr 15, 2025 am 09:57 AMIntroduction This guide explores the powerful combination of Selenium and Python for web automation and testing. Selenium automates browser interactions, significantly improving testing efficiency for large web applications. This tutorial focuses o

A Guide to Understanding Interaction TermsApr 15, 2025 am 09:56 AM

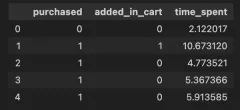

A Guide to Understanding Interaction TermsApr 15, 2025 am 09:56 AMIntroduction Interaction terms are incorporated in regression modelling to capture the effect of two or more independent variables in the dependent variable. At times, it is not just the simple relationship between the control

Swiggy's Hermes: AI Solution for Seamless Data-Driven DecisionsApr 15, 2025 am 09:50 AM

Swiggy's Hermes: AI Solution for Seamless Data-Driven DecisionsApr 15, 2025 am 09:50 AMSwiggy's Hermes: Revolutionizing Data Access with Generative AI In today's data-driven landscape, Swiggy, a leading Indian food delivery service, is leveraging the power of generative AI through its innovative tool, Hermes. Designed to accelerate da

Gaurav Agarwal's Blueprint for Success with RagaAI - Analytics VidhyaApr 15, 2025 am 09:46 AM

Gaurav Agarwal's Blueprint for Success with RagaAI - Analytics VidhyaApr 15, 2025 am 09:46 AMThis episode of "Leading with Data" features Gaurav Agarwal, CEO and founder of RagaAI, a company focused on ensuring the reliability of generative AI. Gaurav discusses his journey in AI, the challenges of building dependable AI systems, a

Grok 2 Image Generator: Shown Angry Elon Musk Holding AR15Apr 15, 2025 am 09:45 AM

Grok 2 Image Generator: Shown Angry Elon Musk Holding AR15Apr 15, 2025 am 09:45 AMGrok-2: Unfiltered AI Image Generation Sparks Ethical Debate Elon Musk's xAI has launched Grok-2, a powerful AI model boasting enhanced chat, coding, and reasoning capabilities, alongside a controversial unfiltered image generator. This release has

Top 10 GitHub Repositories to Master Statistics - Analytics VidhyaApr 15, 2025 am 09:44 AM

Top 10 GitHub Repositories to Master Statistics - Analytics VidhyaApr 15, 2025 am 09:44 AMStatistical Mastery: Top 10 GitHub Repositories for Data Science Statistics is fundamental to data science and machine learning. This article explores ten leading GitHub repositories that provide excellent resources for mastering statistical concept

How to Become Robotics Engineer?Apr 15, 2025 am 09:41 AM

How to Become Robotics Engineer?Apr 15, 2025 am 09:41 AMRobotics: A Rewarding Career Path in a Rapidly Expanding Field The field of robotics is experiencing explosive growth, driving innovation across numerous sectors and daily life. From automated manufacturing to medical robots and autonomous vehicles,

How to Remove Duplicates in Excel? - Analytics VidhyaApr 15, 2025 am 09:20 AM

How to Remove Duplicates in Excel? - Analytics VidhyaApr 15, 2025 am 09:20 AMData Integrity: Removing Duplicates in Excel for Accurate Analysis Clean data is crucial for effective decision-making. Duplicate entries in Excel spreadsheets can lead to errors and unreliable analysis. This guide shows you how to easily remove dup

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Dreamweaver CS6

Visual web development tools

Safe Exam Browser

Safe Exam Browser is a secure browser environment for taking online exams securely. This software turns any computer into a secure workstation. It controls access to any utility and prevents students from using unauthorized resources.

SublimeText3 Linux new version

SublimeText3 Linux latest version

MantisBT

Mantis is an easy-to-deploy web-based defect tracking tool designed to aid in product defect tracking. It requires PHP, MySQL and a web server. Check out our demo and hosting services.

WebStorm Mac version

Useful JavaScript development tools