As various industries begin to have widespread demands for industrial automation and intelligence using image and machine vision technology, machine vision has gradually begun to be applied in industrial sites.

Driven by the government’s favorable policies, the domestic machine vision industry is developing rapidly, and China is becoming one of the most active regions in the world for machine vision development. It is expected that the size of my country's machine vision market will reach 24.6 billion yuan by 2025. Let’s take a deeper look at machine vision.

Machine vision is a comprehensive technology, including image processing, mechanical engineering technology, control, electric light source lighting, optical imaging, sensors, analog and digital video technology, computer software and hardware technology (image enhancement and analysis algorithms, Image card, I/O card, etc.).

A typical machine vision application system includes image capture, light source system, image digitization module, digital image processing module, intelligent judgment and decision-making module and mechanical control execution module.

In general, machine vision is a comprehensive technology that combines software and hardware. It requires software to process images and hardware to provide stable and high-quality images. Both are equally important. As a developer, I am relatively familiar with software modules and have a weaker knowledge base on hardware systems. This article provides a simple summary of hardware-related resources in machine vision. Interested friends may wish to refer to it.

Summary of content:

1. Industrial computer

The industrial computer can be understood as a PC host, but this host is very important in image acquisition and processing and related The controls and interfaces are made stronger. In the machine vision system, the performance of the industrial computer directly affects the processing speed and running time of the entire vision system, and is the key to the entire vision system. The selection of industrial computer needs to consider the following 4 aspects:

1) Size

2) Installation method

3) Configuration

---- --Just choose the appropriate configuration according to your application.

4) Interface

-------It is very important to determine the number of cameras, light source controllers and connection methods in the vision system. For example, the system has 8 cameras and 4 light sources need to be controlled. The cameras are connected through network cables and the light source controller is a 232 interface. This way the number of network interfaces and serial ports of the industrial computer can be determined.

2. Camera

2.1 Camera type

Point array camera/area array camera

Area Array camera: It implements pixel matrix shooting. In images captured by a camera, the details of the image are not determined by the number of pixels, but by the resolution. The resolution is determined by the focal length of the selected lens. For the same camera, the resolution will be different if lenses with different focal lengths are used. The number of pixels does not determine the resolution (sharpness) of the image, so what are the benefits of a camera with large pixels? There is only one answer: reduce the number of shots and increase the test speed.

Line scan camera: As the name suggests, it is in the shape of a "line". Although it is also a two-dimensional image, it is extremely long. The length is several K, but the width is only a few pixels. Generally, this kind of camera is only used in two situations: 1. The field of view to be measured is an elongated strip, which is mostly used for inspection problems on rollers.

2. Requires a huge field of view or extremely high precision. In the second case (requiring a huge field of view or extremely high precision), it is necessary to use an excitation device to excite the camera multiple times, take multiple photos, and then merge the multiple "bar"-shaped images captured. into a huge picture.

Therefore, when using a line array camera, you must use a capture card that can support the line array camera. Line array cameras are expensive, and in the case of large field of view or high-precision detection, their detection speed is also slow - the image of a general camera is 400K ~ 1M, and the combined image is several M as large, and the speed Naturally it is slower. Slow work leads to fine work. For these two reasons, line scan cameras are only used in very special circumstances.

CCD Camera/CMOS Camera

CCD camera can provide good image quality and anti-noise capability, although the size of the system becomes larger due to the addition of external circuits. It can be improved by copying, but the circuit designer can be more flexible and better improve the performance of some special concerns of CCD cameras. CCD is more suitable for applications that require very high camera performance but less stringent cost control, such as astronomy, high-definition medical X-ray images, and other applications that require long-term exposure and have strict requirements on image noise.

CMOS cameras have the advantages of high yield, high integration, low power consumption, and low price. But the image itself has a lot of noise. The current CMOS technology continues to develop, has overcome many of its early shortcomings, and has developed to a level that can compete with CCD technology in terms of image quality.

CMOS is suitable for applications that require small space, small volume, and low power consumption but do not have particularly high image noise and quality requirements. Such as most auxiliary lighting industrial inspection applications, security applications, and most consumer commercial digital cameras. At present, CCD industrial cameras still occupy a dominant position in visual inspection solutions.

2.2 Resolution

The number of pixels each time the camera collects an image generally corresponds to the number of pixels arranged on the target surface of the photoelectric sensor. The choice of resolution also needs to be determined based on the usage scenario and accuracy requirements. Higher is not better.

2.3 Pixel depth

The number of bits per pixel data, the common ones are 8bit, 10bit, and 12bit. Resolution and pixel depth together determine the size of the image. For example, for 5 million pixels with a pixel depth of 8bit, the entire picture should be 5 million*8/1024/1024=37M (1024Byte=1KB, 1024KB=1M). Increasing pixel depth can enhance measurement accuracy, but it also slows down the system and makes system integration more difficult (increased cables, larger size, etc.).

2.4 Frame rate

The speed at which the camera collects and transmits images. For area array cameras, it is generally the number of frames collected per second (Frames/Sec). For line array cameras, it is generally the number of frames collected per second (Frames/Sec). The camera captures the number of lines per second (HZ). The choice of frame rate needs to take into account the dynamic scene being captured.

2.5 Exposure

Industrial line scan cameras are line-by-line exposure methods. You can choose fixed line frequency and external trigger synchronization. The exposure time can be adjusted with the line period. consistent, or you can set a fixed time; area scan cameras have several common methods: frame exposure, field exposure and rolling exposure. Industrial digital cameras generally provide the function of external trigger acquisition, and the shutter speed can generally reach 10ms. High-speed cameras It will be faster.

2.6 Noise

Noise refers to signals outside the actual imaging target that are not expected to be collected during the imaging process. Generally speaking, it is divided into two categories. One is the shot noise caused by the effective signal, which exists for any camera; the other is the noise inherent in the camera itself and has nothing to do with the signal. It is due to the inherent noise caused by the image sensor readout circuit, camera signal processing and amplification circuit. The inherent noise of each camera is different.

2.7 Development interface

For the development of visual projects using cameras, camera control (photography, video recording, saving, setting parameters, etc.) is essential , generally manufacturers will provide control demos, and the control functions need to be applied to our projects during development.

3. Lens

Cameras and lenses are generally matched. The lens selection mainly considers the viewing distance of the image. The lens selection steps are:

1) Calculate the short distance The number of pixels corresponding to the side E=B/C, the number of pixels on the long side and short side of the camera must be greater than E;

2) Pixel size = product short side size B/short side pixels of the selected camera Number

3) Magnification = short film size of the selected camera chip/field of view range of the short side of the camera

4) Resolvable product accuracy = pixel size/magnification (determine whether it is smaller than C )

5) Focal length of objective lens = working distance/(1 1/magnification) Unit: mm

6) The resolution of the image plane must be greater than 1/(2×0.1×magnification ) Unit: lp/mm

The CCD size of the selected lens must be greater than or equal to the size of the camera's CCD sensor chip. In addition, whether the mounting base is a C, CS or F-type interface must also match, and the working distance of the lens must also be considered. , whether there is enough space, etc. If you are still unsure about the choice of lens, you can consult the manufacturer's technical support and let the manufacturer recommend a suitable lens based on your application scenario.

4. Light source

Filling light is a necessary operation in machine vision. If you simply increase the exposure time of the camera, it will increase the noise of the image and reduce the quality of the image. You must choose A suitable light source will do. The selection of light source is divided into two parts: light source lamp and light source controller.

4.1 Light source lamp

Machine vision also provides a wide range of light sources. This is because the vision industry is widely used and it is necessary to choose the appropriate light source according to the specific project. will achieve the desired effect.

Common types of light source lamps are as follows, which can be selected according to specific projects.

4.2 Light source controller

The light source controller is for the test environment Those who provide lighting will generally provide a development interface to control the designated output port to light up or turn off, mainly to cooperate with the camera to provide the software with images that meet the requirements.

5. Physical environment

The machine vision system has relatively high requirements for the test environment, involving issues such as cameras, light sources, and placement of the target to be tested. The principle is to provide a stable, high-performance quality images. The test environment may also need to be designed by a professional organization. If it is a simple environment for experiments, you can purchase experimental brackets online.

The above is the detailed content of What hardware does machine vision contain?. For more information, please follow other related articles on the PHP Chinese website!

Let's Dance: Structured Movement To Fine-Tune Our Human Neural NetsApr 27, 2025 am 11:09 AM

Let's Dance: Structured Movement To Fine-Tune Our Human Neural NetsApr 27, 2025 am 11:09 AMScientists have extensively studied human and simpler neural networks (like those in C. elegans) to understand their functionality. However, a crucial question arises: how do we adapt our own neural networks to work effectively alongside novel AI s

New Google Leak Reveals Subscription Changes For Gemini AIApr 27, 2025 am 11:08 AM

New Google Leak Reveals Subscription Changes For Gemini AIApr 27, 2025 am 11:08 AMGoogle's Gemini Advanced: New Subscription Tiers on the Horizon Currently, accessing Gemini Advanced requires a $19.99/month Google One AI Premium plan. However, an Android Authority report hints at upcoming changes. Code within the latest Google P

How Data Analytics Acceleration Is Solving AI's Hidden BottleneckApr 27, 2025 am 11:07 AM

How Data Analytics Acceleration Is Solving AI's Hidden BottleneckApr 27, 2025 am 11:07 AMDespite the hype surrounding advanced AI capabilities, a significant challenge lurks within enterprise AI deployments: data processing bottlenecks. While CEOs celebrate AI advancements, engineers grapple with slow query times, overloaded pipelines, a

MarkItDown MCP Can Convert Any Document into Markdowns!Apr 27, 2025 am 09:47 AM

MarkItDown MCP Can Convert Any Document into Markdowns!Apr 27, 2025 am 09:47 AMHandling documents is no longer just about opening files in your AI projects, it’s about transforming chaos into clarity. Docs such as PDFs, PowerPoints, and Word flood our workflows in every shape and size. Retrieving structured

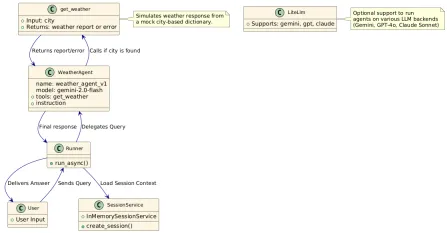

How to Use Google ADK for Building Agents? - Analytics VidhyaApr 27, 2025 am 09:42 AM

How to Use Google ADK for Building Agents? - Analytics VidhyaApr 27, 2025 am 09:42 AMHarness the power of Google's Agent Development Kit (ADK) to create intelligent agents with real-world capabilities! This tutorial guides you through building conversational agents using ADK, supporting various language models like Gemini and GPT. W

Use of SLM over LLM for Effective Problem Solving - Analytics VidhyaApr 27, 2025 am 09:27 AM

Use of SLM over LLM for Effective Problem Solving - Analytics VidhyaApr 27, 2025 am 09:27 AMsummary: Small Language Model (SLM) is designed for efficiency. They are better than the Large Language Model (LLM) in resource-deficient, real-time and privacy-sensitive environments. Best for focus-based tasks, especially where domain specificity, controllability, and interpretability are more important than general knowledge or creativity. SLMs are not a replacement for LLMs, but they are ideal when precision, speed and cost-effectiveness are critical. Technology helps us achieve more with fewer resources. It has always been a promoter, not a driver. From the steam engine era to the Internet bubble era, the power of technology lies in the extent to which it helps us solve problems. Artificial intelligence (AI) and more recently generative AI are no exception

How to Use Google Gemini Models for Computer Vision Tasks? - Analytics VidhyaApr 27, 2025 am 09:26 AM

How to Use Google Gemini Models for Computer Vision Tasks? - Analytics VidhyaApr 27, 2025 am 09:26 AMHarness the Power of Google Gemini for Computer Vision: A Comprehensive Guide Google Gemini, a leading AI chatbot, extends its capabilities beyond conversation to encompass powerful computer vision functionalities. This guide details how to utilize

Gemini 2.0 Flash vs o4-mini: Can Google Do Better Than OpenAI?Apr 27, 2025 am 09:20 AM

Gemini 2.0 Flash vs o4-mini: Can Google Do Better Than OpenAI?Apr 27, 2025 am 09:20 AMThe AI landscape of 2025 is electrifying with the arrival of Google's Gemini 2.0 Flash and OpenAI's o4-mini. These cutting-edge models, launched weeks apart, boast comparable advanced features and impressive benchmark scores. This in-depth compariso

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

PhpStorm Mac version

The latest (2018.2.1) professional PHP integrated development tool

MinGW - Minimalist GNU for Windows

This project is in the process of being migrated to osdn.net/projects/mingw, you can continue to follow us there. MinGW: A native Windows port of the GNU Compiler Collection (GCC), freely distributable import libraries and header files for building native Windows applications; includes extensions to the MSVC runtime to support C99 functionality. All MinGW software can run on 64-bit Windows platforms.

EditPlus Chinese cracked version

Small size, syntax highlighting, does not support code prompt function

DVWA

Damn Vulnerable Web App (DVWA) is a PHP/MySQL web application that is very vulnerable. Its main goals are to be an aid for security professionals to test their skills and tools in a legal environment, to help web developers better understand the process of securing web applications, and to help teachers/students teach/learn in a classroom environment Web application security. The goal of DVWA is to practice some of the most common web vulnerabilities through a simple and straightforward interface, with varying degrees of difficulty. Please note that this software

ZendStudio 13.5.1 Mac

Powerful PHP integrated development environment