Technology peripherals

Technology peripherals AI

AI Breaking the boundaries of power inspection requires these new technologies

Breaking the boundaries of power inspection requires these new technologiesBreaking the boundaries of power inspection requires these new technologies

A drone shuttles between power lines and towers, taking high-precision photos of transmission lines. The photos taken are compressed at a high magnification using algorithms, and combined with the towers through the wireless communication capabilities of the drone. The composite optical fiber overhead ground wire is quickly transmitted to the back-end computer room equipment. After decompression, the restored picture is almost the same as the original picture taken. The picture is analyzed through artificial intelligence, and diagnostic results are quickly generated and sent to the staff. This power inspection model is not only more efficient, but also avoids various safety hazards during manual inspections. This has also become a goal that many countries are striving to achieve in the digital transformation of the power industry.

In the past, in order to ensure the stable operation of power lines and power systems, power supply companies needed to regularly arrange inspection personnel to inspect lines and equipment and discover hidden dangers. However, power inspection has always been a dangerous job. For inspection personnel, not only must it be accurate, but they also need to work in two shifts, which is time-consuming and labor-intensive. Some facilities even require climbing and "steel walking". So”. For power supply companies, since this job is very hard, the cost of employment is naturally not low.

Traditional power inspection - low efficiency and high risk

Now most power cable tunnels, substations, transmission lines, switching stations and other facilities mainly use It is also an inspection method involving manual labor and a small number of environmental monitors.

Traditional power line inspection methods mainly include special marking methods, bar code identification methods and information button collection methods. The special marking method requires marking on the power line tower in advance, and inspection personnel use these marks to confirm the status of the pole. The disadvantage is that it is easily affected by human factors; the barcode identification method also requires affixing a barcode on the pole in advance, and accessing the barcode information To complete the power line inspection, although it is easier to operate than the special marking method, the barcode is easy to be destroyed, and it does not completely get rid of manual management, affecting the accuracy; the information button collection method, by installing information buttons with different numbers, the inspection personnel use handheld The equipment scans the information buttons, accesses and transmits data, and completes the analysis and processing of power line information. However, the installation of the information buttons is more complicated, and the inspection process also requires on-site operations by staff, making it difficult to achieve comprehensive line management.

The traditional line inspection model is not only inefficient but also comes with high risks. It requires workers to climb up the transmission line and "walk the tightrope". In some remote places, it is necessary to climb mountains and ridges to inspect. Due to the condition of equipment and lines, one person can usually only complete the inspection of 2 to 3 towers a day. According to data from the National Energy Administration, a total of 29 accidents occurred in the country in the first three quarters of 2021, with a total of 34 deaths. It can be seen that traditional inspection work is not only inefficient, but also dangerous.

In addition, under the traditional power inspection model, the sense of responsibility, professional ability, work experience and other characteristics of each staff member are also uneven. These factors will also affect the quality and duration of the inspection. For managers, it is difficult to accurately evaluate the work quality of inspection personnel by relying solely on inspection records, resulting in many inspections becoming a mere formality.

Robot - the first step in the digitalization of power inspection

Currently, the domestic power industry is actively responding to the construction of the digital economy and Digital China and carrying out digital transformation. Combining intelligent monitoring equipment with digital management systems will significantly reduce the workload of daily inspections, effectively improve the quality of inspections, and improve management efficiency.

In July this year, at the 5th Digital China Construction Summit, Alibaba demonstrated a "robot electrician" that can automatically inspect the power distribution room after setting a route through the Alibaba Cloud navigation algorithm and use cameras to and the infrared sensor detected a fault. In September of the same year, State Grid Intelligence also launched development cooperation with Alibaba Cloud in the field of navigation systems. The first round focused on wheeled inspection robot products. The autonomous driving positioning and navigation technology of Alibaba DAMO Academy can help optimize the environment of power inspection robots. Perception, map construction and path planning capabilities enable wheeled inspection robots to escape difficulties and recharge independently, improving the stability and intelligence of the robot.

Wheeled robot in substation

This wheeled robot can complete outdoor tasks Centimeter-level high-precision mapping of large scenes, the positioning initialization success rate at any location on the map reaches 98%, and the use of low-cost multi-sensor fusion positioning can achieve "centimeter-level" positioning accuracy and obstacle recognition. The real-time terrain estimation function that integrates multi-sensor observations can complete path planning and select safe routes online to help the robot operate stably in complex terrain conditions.

At this stage, wheeled robots are increasingly involved in power inspection work. They can completely get rid of traditional fixed tracks. However, in the face of complex terrain environments, wheeled robots are difficult to complete this work. In comparison, quadruped robots that can walk on mountain roads and go up and down stairs are much more flexible.

Boston Dynamics Spot quadruped robot

Quadruped robot is also currently being tried Participate in power inspection work, the most famous of which is Spot, which is already sold by Boston Dynamics. Domestic robot manufacturers are also exploring the application scenarios of quadruped robots. For example, Shanghai Power Cable Company is trying to use Jueying Deep in the Cloud to conduct line inspection tests. Although there is still some room for development in quadruped robot technology, whether they are wheeled or quadruped robots, they can provide good ground support for power distribution rooms, substations and other facilities.

These are not the only facilities that need to be inspected in the power industry. Pole towers located in cities, villages, and even mountainous areas require more flexible inspection equipment due to their remote locations and complex environments. UAV-based inspections Inspection mode is gradually being adopted.

Drones - the digital "wings" of power inspections

In mountainous areas, power inspections need to face extreme climate and complex terrain problems at any time. For example, in In the plateau area of Sichuan Province, many of the transmission lines operated and maintained by Sichuan Power Transmission and Transformation Company are built on steep cliffs. Most of the towers are over 3,000 meters above sea level. In high-altitude environments, the thin air will cause the lift to be significantly reduced. Drones need to consume more power to maintain their flight altitude, which affects battery life.

DJI has adapted the Inspire 2 with plateau paddles, which can ensure stable flight at an altitude of 5,000 meters, and can also carry out normal power inspection operations in the Sichuan plateau mountainous areas. In addition, the DJI Phantom 4 and Mavic 2 series drones are equipped with universal propellers, which can also fly safely at an altitude of 6,000 meters without changing the propellers according to the altitude.

DJI drone flying in high altitude areas

For long endurance According to the demand, the DJI Matrice 200 V2 series is equipped with a high-capacity TB55 battery, which reserves 15 to 20% of the landing power. Only the Zenmuse X5S or Zenmuse Z30 single gimbal load is installed. The Matrice 200 V2 series has a battery life of power inspection in plateau mountainous areas. It can last up to 22 to 27 minutes and can better adapt to the harsh flight environment at high altitudes.

Although the combined use of drones, robots and cameras can significantly reduce the labor cost of power inspections, due to size limitations, these devices often only have functions such as high-precision photography and automatic navigation. Strictly speaking, taking photos and sending them back is only half of the inspection work. Making the other half of the work smart requires upgrading back-end facilities.

Artificial intelligence - the "most powerful brain" of power inspection

The pictures captured by the equipment during the inspection can be quickly transmitted to the back-end equipment through the 5G network , combined with artificial intelligence, can automatically complete the analysis of pictures.

Inspur’s “Artificial Intelligence Solution for Power Equipment Inspection” works exactly like this. It uses artificial intelligence technology to identify and analyze on-site power equipment pictures, complete sample data preparation, model training, and model application. The pictures collected by drones, robots and other equipment are transmitted to the detection server deployed in the power station studio for identification, and intelligent diagnosis is quickly completed.

Similar combinations have also been adopted by power supply companies in some areas. State Grid Ningbo Power Supply Company and China Mobile jointly developed a 5G drone autonomous inspection application. The drone can fly from the nest to the inspection point according to the established route, and uses its own high-definition camera to capture detailed shots of insulators and towers. Details such as ground wires are transmitted back in real time through the 5G network. Once a safety hazard is identified, the drone will automatically trigger the processing mechanism to eliminate the hazard as soon as possible. After completing the task, it will automatically and accurately land back to the nest.

State Grid Shandong Electric Power Company Qingdao Power Supply Company has also independently developed a "5G Beidou-based drone intelligent inspection system" and built a 5G SA power slicing network data high-speed and safe transmission system, combined with artificial intelligence based on deep learning algorithms The intelligent diagnosis and analysis platform can realize autonomous drone inspections, real-time data transmission, and intelligent defect analysis. It is the first in China to form a precise and intelligent drone inspection method based on the Beidou system.

Written at the end

With the support of new technologies, power inspection work has become more efficient. Public information shows that after the Shenzhen Power Supply Bureau adopted autonomous drone inspections, the efficiency increased by 2.6 times compared with traditional manual inspections; Foshan Gaoming Power Supply Bureau also achieved full coverage of autonomous drone inspections and built 385 smart power rooms.

In the future, as the penetration rate of power inspection robots and drones increases, the probability of accidents in my country's power industry will also decrease, and the inherent high-risk industry characteristics of power operations and inspections are also expected to change. Power inspection using robots and drones combined with new technologies such as 5G and artificial intelligence is also an important means of realizing the development of intelligent and automated power grids.

The above is the detailed content of Breaking the boundaries of power inspection requires these new technologies. For more information, please follow other related articles on the PHP Chinese website!

How to Run LLM Locally Using LM Studio? - Analytics VidhyaApr 19, 2025 am 11:38 AM

How to Run LLM Locally Using LM Studio? - Analytics VidhyaApr 19, 2025 am 11:38 AMRunning large language models at home with ease: LM Studio User Guide In recent years, advances in software and hardware have made it possible to run large language models (LLMs) on personal computers. LM Studio is an excellent tool to make this process easy and convenient. This article will dive into how to run LLM locally using LM Studio, covering key steps, potential challenges, and the benefits of having LLM locally. Whether you are a tech enthusiast or are curious about the latest AI technologies, this guide will provide valuable insights and practical tips. Let's get started! Overview Understand the basic requirements for running LLM locally. Set up LM Studi on your computer

Guy Peri Helps Flavor McCormick's Future Through Data TransformationApr 19, 2025 am 11:35 AM

Guy Peri Helps Flavor McCormick's Future Through Data TransformationApr 19, 2025 am 11:35 AMGuy Peri is McCormick’s Chief Information and Digital Officer. Though only seven months into his role, Peri is rapidly advancing a comprehensive transformation of the company’s digital capabilities. His career-long focus on data and analytics informs

What is the Chain of Emotion in Prompt Engineering? - Analytics VidhyaApr 19, 2025 am 11:33 AM

What is the Chain of Emotion in Prompt Engineering? - Analytics VidhyaApr 19, 2025 am 11:33 AMIntroduction Artificial intelligence (AI) is evolving to understand not just words, but also emotions, responding with a human touch. This sophisticated interaction is crucial in the rapidly advancing field of AI and natural language processing. Th

12 Best AI Tools for Data Science Workflow - Analytics VidhyaApr 19, 2025 am 11:31 AM

12 Best AI Tools for Data Science Workflow - Analytics VidhyaApr 19, 2025 am 11:31 AMIntroduction In today's data-centric world, leveraging advanced AI technologies is crucial for businesses seeking a competitive edge and enhanced efficiency. A range of powerful tools empowers data scientists, analysts, and developers to build, depl

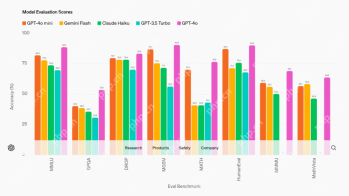

AV Byte: OpenAI's GPT-4o Mini and Other AI InnovationsApr 19, 2025 am 11:30 AM

AV Byte: OpenAI's GPT-4o Mini and Other AI InnovationsApr 19, 2025 am 11:30 AMThis week's AI landscape exploded with groundbreaking releases from industry giants like OpenAI, Mistral AI, NVIDIA, DeepSeek, and Hugging Face. These new models promise increased power, affordability, and accessibility, fueled by advancements in tr

Perplexity's Android App Is Infested With Security Flaws, Report FindsApr 19, 2025 am 11:24 AM

Perplexity's Android App Is Infested With Security Flaws, Report FindsApr 19, 2025 am 11:24 AMBut the company’s Android app, which offers not only search capabilities but also acts as an AI assistant, is riddled with a host of security issues that could expose its users to data theft, account takeovers and impersonation attacks from malicious

Everyone's Getting Better At Using AI: Thoughts On Vibe CodingApr 19, 2025 am 11:17 AM

Everyone's Getting Better At Using AI: Thoughts On Vibe CodingApr 19, 2025 am 11:17 AMYou can look at what’s happening in conferences and at trade shows. You can ask engineers what they’re doing, or consult with a CEO. Everywhere you look, things are changing at breakneck speed. Engineers, and Non-Engineers What’s the difference be

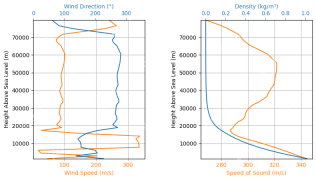

Rocket Launch Simulation and Analysis using RocketPy - Analytics VidhyaApr 19, 2025 am 11:12 AM

Rocket Launch Simulation and Analysis using RocketPy - Analytics VidhyaApr 19, 2025 am 11:12 AMSimulate Rocket Launches with RocketPy: A Comprehensive Guide This article guides you through simulating high-power rocket launches using RocketPy, a powerful Python library. We'll cover everything from defining rocket components to analyzing simula

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

SecLists

SecLists is the ultimate security tester's companion. It is a collection of various types of lists that are frequently used during security assessments, all in one place. SecLists helps make security testing more efficient and productive by conveniently providing all the lists a security tester might need. List types include usernames, passwords, URLs, fuzzing payloads, sensitive data patterns, web shells, and more. The tester can simply pull this repository onto a new test machine and he will have access to every type of list he needs.

WebStorm Mac version

Useful JavaScript development tools

ZendStudio 13.5.1 Mac

Powerful PHP integrated development environment

Safe Exam Browser

Safe Exam Browser is a secure browser environment for taking online exams securely. This software turns any computer into a secure workstation. It controls access to any utility and prevents students from using unauthorized resources.

MinGW - Minimalist GNU for Windows

This project is in the process of being migrated to osdn.net/projects/mingw, you can continue to follow us there. MinGW: A native Windows port of the GNU Compiler Collection (GCC), freely distributable import libraries and header files for building native Windows applications; includes extensions to the MSVC runtime to support C99 functionality. All MinGW software can run on 64-bit Windows platforms.