Technology peripherals

Technology peripherals AI

AI MIT's latest achievement: This 'self-replicating' robot can build everything from airplanes to rockets!

MIT's latest achievement: This 'self-replicating' robot can build everything from airplanes to rockets!How outrageous are the abilities of today’s robots?

It’s really unimaginable. Even building airplanes and rockets has become a small case. They can even build themselves! Really promising.

Recently, a paper by MIT researchers was published in the journal Nature Communications Engineering.

The paper was co-published by Center for Bits and Atoms (CBA) doctoral student Amira Abdel-Rahman, professor and CBA director Neil Gershenfeld, and three others who have made significant progress in creating robots. Results.

Paper address: https://www. php.cn/link/1b742ae215adf18b75449c6e272fd92d

It is understood that the latest robot developed by Gershenfeld’s research team can assemble almost anything quickly and effectively. Including objects much larger than yourself, from vehicles to buildings to larger robots and more.

The team has shown that both the assembly robots and the structural components being built can be composed of the same subunits, and that the robots can operate independently in large numbers Move quickly to complete large-scale assembly.

Based on the standardized design of the same structure, this also means that this robot can "effortlessly" assemble a new version of itself.

"Constructing a self-replicating system is not only a classic challenge in #, but even a classic in science fiction literature Challenge," said Sandor Fekete, professor of algorithms at the Department of Computer Science at the Technical University of Braunschweig in Germany. "So far, only nature has truly achieved this. So their work is very exciting People’s hearts!」

The “big dream” of small voxels

Voxel is a very tiny sub-unit, equivalent to the volume component of a two-dimensional pixel. As with previous experiments, the new system involves large, usable structures built from voxel arrays.

However, unlike the voxels of early mechanical structures, the voxels used by Gershenfeld's research team are more "complex", and can be made from one unit Carry power and data to the next unit.

This allows the structure to be built not only to withstand loads, but also to lift, move and manipulate materials - even the voxels themselves.

Early versions of assembly robots had bundles of wires connected to their power and control systems, Gershenfeld said, but “we built the These structures create an "intelligent system" that allows voxels to transmit power, data, and power regardless of wires."

The robot itself consists of a string of several voxels connected end-to-end. These voxels can grab hold of another voxel using a connection point at one end, then move like a worm to the desired location, attach to the growing structure and release there.

Robot path optimization algorithm, the world’s first

Gershenfeld explained that while the early systems demonstrated by his group members could in principle build arbitrarily large structures, the process becomes more complex when the size of those structures reaches a certain size compared to the size of the assembly robots. It is becoming more and more inefficient, "because each robot must take a longer path to bring the parts to the destination."

With their newly developed system, the robot can decide Whether to build a larger version that can reach greater distances and reduce "commute" time.

Building a larger structure may require another such step. Bigger robots are created from new, larger robots, while building finely detailed structures may require more help from the smallest robots.

Abdel-Rahman said that when these robotic devices work on assembling things, they face choices every step of the way.

"It can build a structure, it can build another robot of the same size, it can also build a larger robot."

"We have been working on creating a decision optimization algorithm for this part of the work."

"For example, If you want to build a cone or a hemisphere," she said, "how do you start path planning and how do you divide that shape into different areas where different robots can work?"

The software they developed allows someone to input a shape and get an output that shows where to place the first block, and every block after that, based on the distance that needs to be traversed.

Gershenfeld said that although there have been thousands of papers published on robot route planning, “the next steps, when the robot must When making a decision, building another robot or a different kind of robot, This is a completely new job, and there is no precedent to refer to."

Research Limitations

While the experimental system can be assembled and include power and data links, in its current version the connectors between the tiny sub-units are still not strong enough , unable to bear the necessary load. Miana Smith, a graduate student on the team, is working on developing more powerful connectors.

Gershenfeld said: "These robots can walk and they can place parts, but we haven't reached the point where one robot builds another robot and then it's gone."

"To make this situation a reality, we also need the support of some emerging technologies, such as the power of actuators and the strength of joints."

MIT computer scientist Neil Gershenfeld

##Gershenfeld also said that a fully autonomous self-replicating robot assembly system is both Being able to assemble larger structures, including larger robots, and plan the best construction sequence - This may still take a few years.

But this work is already an important step toward that goal, including solving the complex tasks of when to build more robots, how big of a robot to make, and How to organize robots of different sizes to build a structure in an orderly manner.

From airplanes to rockets, the application potential of new technologies is huge

The application potential of this achievement is huge, because it is likely to be used tobuild various large-scale, High value structure.

For example, now when building an aircraft, you first need a huge factory, the factory is even much larger than the parts they are building, plus other aircraft may often be needed to transport manufacturing raw materials needed for aircraft.

With such a system of tiny parts assembled by microrobots, "the final assembly of the aircraft will become the only assembly process," Gershenfeld said .

Similarly, in building a car, "you might spend a year building the tooling" before the first car is actually built, he said, but with the new system The emergence of will obviously bypass this process.

This potential efficiency is why Gershenfeld and his students have been working closely with car companies, airlines and aerospace agencies.

Even the relatively low-tech construction industry is likely to benefit from this technology in the future.

Interest in 3D printed homes has grown in recent years, but these homes now require printing machines that are as large or larger than the homes being built. The use of such micro-robots can apparently effectively solve this problem.

Aaron Becker, associate professor in the Department of Electrical and Computer Engineering at the University of Houston, gave the work the highest possible rating, calling it 『Home run』:

"They have created an innovative hardware system, a new way of thinking about expanding the robot population. method, and a rigorous set of algorithms."

"This paper examines a key area of reconfigurable systems: how to rapidly scale a robotic workforce and use it to efficiently Assemble the materials into the required structure."

"This is the first time I have seen such work!"

The above is the detailed content of MIT's latest achievement: This 'self-replicating' robot can build everything from airplanes to rockets!. For more information, please follow other related articles on the PHP Chinese website!

机器人学我表情的样子,让人感到一丝恐惧Apr 09, 2023 am 10:11 AM

机器人学我表情的样子,让人感到一丝恐惧Apr 09, 2023 am 10:11 AM通常,机器人的主要功能是完成一些简单的操作任务,我们希望机器人可以模仿人,让能力尽可能接近人类水平。不论是小米的 CyberOne 还是特斯拉的 Optimus,人们关心的主要是其机械关节数量,控制算法和行走速度。不过在这个领域,有些人探索的方向更加脑洞大开:现在,有一种机器人把模仿真人表情做到了极致:先尝试一下自拍。从「嫌弃」到「惊讶」,都可以做到完全同步:这个机器人名叫 Ameca,是个表情怪。除了模仿,它自己也能照镜子做很多小表情,看起来非常像真人。Ameca「假装」第一次见到镜子,首

拿破仑、孔子在线陪聊!AI聊天机器人「复活」历史名人,网友:真上头!Apr 08, 2023 pm 12:11 PM

拿破仑、孔子在线陪聊!AI聊天机器人「复活」历史名人,网友:真上头!Apr 08, 2023 pm 12:11 PM和活生生的已故历史名人聊天是个什么感觉?近日,就有一群开发者利用语言模型,把千百年来各行各业的历史名人全部「复活」成了聊天机器人,做进了一款手机app里,起名叫「你好,历史」!开发者声称,这个与古代名人聊天的app涉及的内容几乎无所不包。比如可以:与玛丽莲·梦露聊好莱坞八卦与弗里达·卡洛讨论现代艺术问问圣诞老人他有多少只驯鹿问问科特·科本为什么自杀向穴居人学习如何生火与宇宙意识辩论生命的意义不过他们也没忘记提醒用户,这些对话是由人工智能生成的,所以不要太认真。而且每个对话都是独一无二的,你永远不

女王登基70周年,世上首个超逼真人形机器艺术家献上肖像画作,被锐评“缺少信念”Apr 08, 2023 pm 08:11 PM

女王登基70周年,世上首个超逼真人形机器艺术家献上肖像画作,被锐评“缺少信念”Apr 08, 2023 pm 08:11 PM大数据文摘出品作者:Caleb为庆祝英国女王伊丽莎白二世登基70周年,英国也是早早就洋溢出了庆典的味道。据了解,英国将于6月2日至5日连放4天公众假期,并在期间举行多项庆祝活动。英国皇家铸币厂也在精心打造有史以来最大的硬币,直径220毫米,重15公斤,面值15000英镑,耗时近400小时打造,是该厂1100年来生产的最大硬币。这枚金币一面雕刻着代表英国女王伊丽莎白二世的符号EⅡR,周围环绕着代表英国的玫瑰、水仙、蓟和三叶草。另一面有女王骑在马背上的图案。在这么热闹的日子里,AI当然也必须来凑一凑

人类与人工智能如何建立关系Apr 09, 2023 pm 07:41 PM

人类与人工智能如何建立关系Apr 09, 2023 pm 07:41 PM人类与人工智能相比,哪个更擅长建立关系?事实上,这项革命性的技术已经存在了很长一段时间。然而,直到最近人们才意识到人工智能对人类的重要性。人工智能利用算法模拟人类,并随着时间的推移从经验中学习的能力,为这项技术与人类建立关系开辟道路。人类如何建立人际关系作为人类,我们倾向于只与少数人建立关系。我们试图确保不需要的和不相干的人从我们的生活中消失。在将我们的关系限制在少数人的同时,我们确保与那些对我们真正重要的人建立高质量的关系。然而,同样的方法在商业用语中可能不是理想的,并可能适得其反。尽管知道这

盘点全球不错的七所机器人工程专业学校Apr 08, 2023 pm 01:31 PM

盘点全球不错的七所机器人工程专业学校Apr 08, 2023 pm 01:31 PM有抱负的工程师应该了解世界各地著名的机器人工程学院。现在是从事机器人和工程事业的最佳时机——从人工智能到太空探索,这一领域充满了令人兴奋的创新和进步。美国劳工统计局估计,未来10年,机械工程领域的职业总体上将保持7%的稳定增长率,确保毕业生将有大量的就业机会。机器人工程专业的学生平均工资超过9万美元,无需担心还助学贷款的问题。对于那些考虑投身机器人工程领域的人来说,选择一所合适的大学是非常重要的。世界上许多顶尖的机器人工程学院都在美国,尽管国外也有一些很棒的项目。这是7所世界上最好的机器人工程学

让机器人学会咖啡拉花,得从流体力学搞起!CMU&MIT推出流体模拟平台Apr 07, 2023 pm 04:46 PM

让机器人学会咖啡拉花,得从流体力学搞起!CMU&MIT推出流体模拟平台Apr 07, 2023 pm 04:46 PM机器人也能干咖啡师的活了!比如让它把奶泡和咖啡搅拌均匀,效果是这样的:然后上点难度,做杯拿铁,再用搅拌棒做个图案,也是轻松拿下:这些是在已被ICLR 2023接收为Spotlight的一项研究基础上做到的,他们推出了提出流体操控新基准FluidLab以及多材料可微物理引擎FluidEngine。研究团队成员分别来自CMU、达特茅斯学院、哥伦比亚大学、MIT、MIT-IBM Watson AI Lab、马萨诸塞大学阿默斯特分校。在FluidLab的加持下,未来机器人处理更多复杂场景下的流体工作也都

四足机器人学会“双腿站立下楼梯”!效率比腿式系统高83%Apr 09, 2023 am 11:21 AM

四足机器人学会“双腿站立下楼梯”!效率比腿式系统高83%Apr 09, 2023 am 11:21 AM还记得那个和特斯拉飙车的机器人吗?这是瑞士苏黎世联邦理工学院衍生公司研发的与公司同名的四足轮腿式机器人——Swiss-Mile,前身是ANYmal四足机器人。距离它和特斯拉飙车还不到半年的时间,它又实现了重大升级。这次升级改进了机器人的算法,运动能力直接UP UP UP ! 可以双腿站立下楼梯:(小编内心OS:如果是我穿轮滑鞋下楼梯可能会摔个狗吃屎)楼梯爬累了,坐个电梯吧,用前脚按开电梯门:面对障碍物应对自如:它还能知道什么时候该站起来,什么时候该“趴下”,双腿直立与四足运动之间的切换更丝滑:

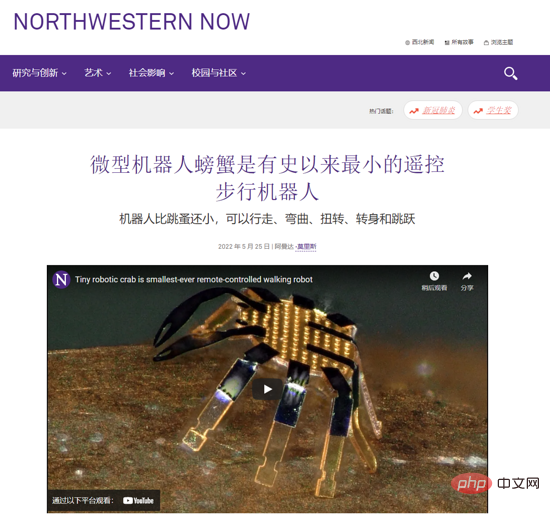

科学家展示世界上有史以来超小的“螃蟹”遥控步行机器人,体积比跳蚤还小Apr 09, 2023 pm 10:41 PM

科学家展示世界上有史以来超小的“螃蟹”遥控步行机器人,体积比跳蚤还小Apr 09, 2023 pm 10:41 PM日前,美国西北大学工程师开发出有史以来最小的遥控步行机器人,它以一种小巧可爱的螃蟹形式出现。这种微小的“螃蟹”机器人宽度只有半毫米,可以弯曲、扭曲、爬行、行走、转弯甚至跳跃,无需液压或电力。IT之家了解到,相关研究成果发表在《科学・机器人》上。据介绍,这种机器人是用形状记忆合金材料所制造的,然后可以变成所需的形状,当你加热后又会变回原来的形状,而热量消失时可以再次弹回变形时的样子。据介绍,其热量是由激光所带来的。激光通过“螃蟹”加热合金,但因为它们非常小,所以热量传播非常快,这使得它们的响应速度

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

SublimeText3 English version

Recommended: Win version, supports code prompts!

Safe Exam Browser

Safe Exam Browser is a secure browser environment for taking online exams securely. This software turns any computer into a secure workstation. It controls access to any utility and prevents students from using unauthorized resources.

Zend Studio 13.0.1

Powerful PHP integrated development environment

DVWA

Damn Vulnerable Web App (DVWA) is a PHP/MySQL web application that is very vulnerable. Its main goals are to be an aid for security professionals to test their skills and tools in a legal environment, to help web developers better understand the process of securing web applications, and to help teachers/students teach/learn in a classroom environment Web application security. The goal of DVWA is to practice some of the most common web vulnerabilities through a simple and straightforward interface, with varying degrees of difficulty. Please note that this software

mPDF

mPDF is a PHP library that can generate PDF files from UTF-8 encoded HTML. The original author, Ian Back, wrote mPDF to output PDF files "on the fly" from his website and handle different languages. It is slower than original scripts like HTML2FPDF and produces larger files when using Unicode fonts, but supports CSS styles etc. and has a lot of enhancements. Supports almost all languages, including RTL (Arabic and Hebrew) and CJK (Chinese, Japanese and Korean). Supports nested block-level elements (such as P, DIV),