Technology peripherals

Technology peripherals AI

AI Multiple drones collaborate to 3D print a house, and the research appears on the cover of Nature

Multiple drones collaborate to 3D print a house, and the research appears on the cover of NatureMultiple drones collaborate to 3D print a house, and the research appears on the cover of Nature

We can often see bees, ants and other animals busy building nests. After natural selection, their work efficiency is astonishingly high

The ability of these animals to divide and cooperate has been "passed on" to drones. A study from Imperial College London tells us Showing the future direction, like this:

Drone 3D dusting:

This research result appeared on the cover of "Nature" on Wednesday.

##Paper address: https://www.nature.com/articles/s41586-022-04988-4

To demonstrate the capabilities of the drones, the researchers used foam and a special lightweight cement material to build structures ranging in height from 0.18 meters to 2.05 meters. The error compared to the original blueprint was less than 5mm.

To prove that the system could handle more complex drone formations, the team created a light-trace time-lapse using lights on the drones sequence, simulating the creation of a tall dome-like structure.

.

Mirko Kovac, the leader of the research and director of the Aerial Robotics Laboratory at Imperial College London, said: This method could be used to build buildings in the Arctic or even Mars, or to help repair normally expensive Scaffolding for high-rise buildings.

However, the technology is currently subject to some limitations, as drones are difficult to carry heavy loads, require regular charging, and still require human supervision. However, the researchers say they hope to alleviate some of these issues by automatically charging the drones during research projects.

How is drone 3D printing implemented? In this regard, researchers have constructed a sophisticated system.

Research IntroductionTo improve productivity and safety, robot-based construction technologies have been proposed for the assembly of building components and free-form continuous additives Manufacturing (AM, additive manufacturing). Compared to assembly-based methods, free-form continuous AM enables the flexible production of geometrically variable designs with high efficiency and low cost. However, these large systems need to be connected to a power source, are inconvenient for inspection, maintenance, and repair, and are difficult to manufacture in harsh environments.

As an alternative to large individual robot systems, small mobile robots can offer greater flexibility and scalability. However, research into using robot formations for construction is still in the early exploratory stages of development. In addition, the current operating height of multi-robots is limited and cannot operate beyond a certain range. The figure below shows a comparison between SOTA robotic platforms developed for AM in the construction industry.

Natural builders have shown greater adaptability when building than current robotic systems and their inherent limitations, with many Do this with the help of fly-in and additive construction methods. For example, a swallow can make 1200 flights between the source of materials and the site of construction to gradually complete the nest. Social insects such as termites and wasps demonstrate a greater degree of adaptability and scalability: Aerial construction by social wasps demonstrated efficient and direct path optimization, easing the need to navigate throughout the construction process.

These natural systems inspire approaches to collective construction using multi-agents that require solving multi-agent coordination problems beyond currently available technologies. In addition to collective interaction methods for multi-robot systems, material design and use and environmental manipulation mechanisms must be integrated and co-developed to enable cooperative construction.

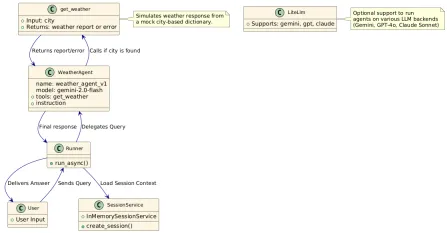

The system proposed by Imperial College is called Aerial-AM, which combines biological cooperation mechanisms with engineering principles and uses multiple drones to achieve it.

The UAV team’s realization of autonomous additive manufacturing requires the parallel development of a number of key technologies, including: 1) Aerial robots capable of high-precision material deposition and print quality, and real-time qualitative assessment ; 2) Aerial robot teams can broadcast their activities to each other and share data wirelessly without interfering with each other; 3) Autonomous navigation and task planning system, combined with printing path strategy to adaptively determine and allocate manufacturing tasks; 4) Design or selection of material planning , specifically a lightweight and printable cement mixture suitable for aerial additive manufacturing methods without the need for formwork or temporary scaffolding.

Aerial-AM uses two types of aerial robotic platforms, called BuildDrone and ScanDrone. The BuildDrone is used to stack physical materials, and the ScanDrone is used to perform augmentation after each layer of material is deposited. Aerial scanning and verification observations. Both robotic platforms are coordinated on their respective workflows via a distributed multi-agent approach. The build cycle includes in-flight print performance characterization of the BuildDrones and ScanDrone, real-time trajectory adaptation and material printing of the BuildDrones, and validation of print results with ScanDrone and human supervisors.

Figure 2. Aerial-AM framework for unconstrained and unbounded AM.

The multi-agent Aerial-AM framework proposed by the new research consists of two loops, running on the slow time scale of planning and the fast time scale of real-time operation, using for manufacturing and progress observation. In a proof-of-concept, researchers used a ScanDrone airborne vision system to perform 3D scans to map progress, building a large cylinder out of expanded foam material.

Figure 3. Aerial-AM BuildDrone prints 2.05 m high cylindrical geometry with 72 passes of material deposition, and real-time print evaluation by ScanDrone.

## Figure 4. Two BuildDrones 3D printing thin-walled cylinders using an error-compensated delta robot to deposit cement Material.

Figure 5. Aerial-AM multi-robot optical track virtual printing dome-shaped rotating surface. a, c are flight trajectories, b, d are top and perspective views. f shows simulation results using 15 robots to print an enlarged version of the geometry with a base diameter of 15 m.

Using BuildDrone’s material deposition and ScanDrone’s real-time qualitative assessment of printed structures, researchers successfully printed cylinders up to 2.05 meters high, demonstrating the Aerial-AM method of manufacturing Ability to handle large geometric objects. Experiments on the fabrication of cementitious thin-walled cylinders demonstrated that the coupling of a self-aligned parallel delta robot with a BuildDrone allows the deposition of material in the lateral and vertical directions with high precision (maximum 5 mm position error), a level well within the limits allowed by UK construction requirements .

Virtual light track AM and simulation results show that the Aerial-AM framework can effectively print a variety of geometries through parallel multi-robot manufacturing while resolving congestion and completing autonomous tasks under abnormal conditions. adapt.

While these experiments successfully demonstrated the feasibility of Aerial-AM, they were only a first step in exploring the potential of using aerial robots for construction. Researchers said that in order to realize 3D printing of houses with drones, significant progress is needed in robotics and materials science, especially in cutting-edge areas such as the deposition of support materials, the solidification of active materials, and task sharing among multiple robots. develop.

As for the UAV itself, in order to bring the research results out of the laboratory, researchers are planning to implement multi-sensor simultaneous positioning and mapping (SLAM) with differential global positioning system (GPS). ) system to provide adequate outdoor positioning.

Once practical, Aerial-AM may provide an alternative way to support housing and critical infrastructure in remote areas.

The above is the detailed content of Multiple drones collaborate to 3D print a house, and the research appears on the cover of Nature. For more information, please follow other related articles on the PHP Chinese website!

Let's Dance: Structured Movement To Fine-Tune Our Human Neural NetsApr 27, 2025 am 11:09 AM

Let's Dance: Structured Movement To Fine-Tune Our Human Neural NetsApr 27, 2025 am 11:09 AMScientists have extensively studied human and simpler neural networks (like those in C. elegans) to understand their functionality. However, a crucial question arises: how do we adapt our own neural networks to work effectively alongside novel AI s

New Google Leak Reveals Subscription Changes For Gemini AIApr 27, 2025 am 11:08 AM

New Google Leak Reveals Subscription Changes For Gemini AIApr 27, 2025 am 11:08 AMGoogle's Gemini Advanced: New Subscription Tiers on the Horizon Currently, accessing Gemini Advanced requires a $19.99/month Google One AI Premium plan. However, an Android Authority report hints at upcoming changes. Code within the latest Google P

How Data Analytics Acceleration Is Solving AI's Hidden BottleneckApr 27, 2025 am 11:07 AM

How Data Analytics Acceleration Is Solving AI's Hidden BottleneckApr 27, 2025 am 11:07 AMDespite the hype surrounding advanced AI capabilities, a significant challenge lurks within enterprise AI deployments: data processing bottlenecks. While CEOs celebrate AI advancements, engineers grapple with slow query times, overloaded pipelines, a

MarkItDown MCP Can Convert Any Document into Markdowns!Apr 27, 2025 am 09:47 AM

MarkItDown MCP Can Convert Any Document into Markdowns!Apr 27, 2025 am 09:47 AMHandling documents is no longer just about opening files in your AI projects, it’s about transforming chaos into clarity. Docs such as PDFs, PowerPoints, and Word flood our workflows in every shape and size. Retrieving structured

How to Use Google ADK for Building Agents? - Analytics VidhyaApr 27, 2025 am 09:42 AM

How to Use Google ADK for Building Agents? - Analytics VidhyaApr 27, 2025 am 09:42 AMHarness the power of Google's Agent Development Kit (ADK) to create intelligent agents with real-world capabilities! This tutorial guides you through building conversational agents using ADK, supporting various language models like Gemini and GPT. W

Use of SLM over LLM for Effective Problem Solving - Analytics VidhyaApr 27, 2025 am 09:27 AM

Use of SLM over LLM for Effective Problem Solving - Analytics VidhyaApr 27, 2025 am 09:27 AMsummary: Small Language Model (SLM) is designed for efficiency. They are better than the Large Language Model (LLM) in resource-deficient, real-time and privacy-sensitive environments. Best for focus-based tasks, especially where domain specificity, controllability, and interpretability are more important than general knowledge or creativity. SLMs are not a replacement for LLMs, but they are ideal when precision, speed and cost-effectiveness are critical. Technology helps us achieve more with fewer resources. It has always been a promoter, not a driver. From the steam engine era to the Internet bubble era, the power of technology lies in the extent to which it helps us solve problems. Artificial intelligence (AI) and more recently generative AI are no exception

How to Use Google Gemini Models for Computer Vision Tasks? - Analytics VidhyaApr 27, 2025 am 09:26 AM

How to Use Google Gemini Models for Computer Vision Tasks? - Analytics VidhyaApr 27, 2025 am 09:26 AMHarness the Power of Google Gemini for Computer Vision: A Comprehensive Guide Google Gemini, a leading AI chatbot, extends its capabilities beyond conversation to encompass powerful computer vision functionalities. This guide details how to utilize

Gemini 2.0 Flash vs o4-mini: Can Google Do Better Than OpenAI?Apr 27, 2025 am 09:20 AM

Gemini 2.0 Flash vs o4-mini: Can Google Do Better Than OpenAI?Apr 27, 2025 am 09:20 AMThe AI landscape of 2025 is electrifying with the arrival of Google's Gemini 2.0 Flash and OpenAI's o4-mini. These cutting-edge models, launched weeks apart, boast comparable advanced features and impressive benchmark scores. This in-depth compariso

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Atom editor mac version download

The most popular open source editor

SecLists

SecLists is the ultimate security tester's companion. It is a collection of various types of lists that are frequently used during security assessments, all in one place. SecLists helps make security testing more efficient and productive by conveniently providing all the lists a security tester might need. List types include usernames, passwords, URLs, fuzzing payloads, sensitive data patterns, web shells, and more. The tester can simply pull this repository onto a new test machine and he will have access to every type of list he needs.

Dreamweaver CS6

Visual web development tools

SublimeText3 Chinese version

Chinese version, very easy to use

DVWA

Damn Vulnerable Web App (DVWA) is a PHP/MySQL web application that is very vulnerable. Its main goals are to be an aid for security professionals to test their skills and tools in a legal environment, to help web developers better understand the process of securing web applications, and to help teachers/students teach/learn in a classroom environment Web application security. The goal of DVWA is to practice some of the most common web vulnerabilities through a simple and straightforward interface, with varying degrees of difficulty. Please note that this software