Technology peripherals

Technology peripherals AI

AI What systems does an industrial robot consist of? What is the role of each?

What systems does an industrial robot consist of? What is the role of each?What systems does an industrial robot consist of? What is the role of each?

A robot is a machine that has more degrees of freedom in three-dimensional space and can realize many anthropomorphic actions and functions, while industrial robots are robots used in industrial production. Its characteristics are: programmability, anthropomorphism, versatility, and mechatronics.

#What are the system components of industrial robots?

1. Main body

The main body is the machine base and actuator, including the big arm, forearm, wrist and hand, which constitute a multi-degree-of-freedom mechanical system. Some robots also have walking mechanisms. Industrial robots have 6 degrees of freedom or even more. The wrist generally has 1 to 3 degrees of freedom of movement.

2. Drive system

The transmission device that makes the robot run. According to the power source, it is divided into three categories: hydraulic, pneumatic and electric. These three types can also be combined into a composite drive system based on requirements. Or indirectly driven through mechanical transmission mechanisms such as synchronous belts, gear trains, and gears. The drive system has a power device and a transmission mechanism, which are used to implement the corresponding actions of the mechanism. Each of these three types of basic drive systems has its own characteristics. The current mainstream is the electric drive system.

3. Control system

controls the robot's actuator to complete specified movements and functions based on the robot's work instruction program and the signal fed back from the sensor.

Highly cost-effective microprocessors have brought new development opportunities to robot controllers, making it possible to develop low-cost, high-performance robot controllers. In order to make the system have sufficient computing and storage capabilities, robot controllers are now mostly composed of powerful ARM series, DSP series, POWERPC series, Intel series and other chips.

4. Perception system

is composed of an internal sensor module and an external sensor module to obtain information on internal and external environmental status.

Internal sensors: Sensors used to detect the status of the robot itself (such as the angle between the arms), mostly sensors that detect position and angle. Specifically: position sensor, position sensor, angle sensor, etc.

External sensors: Sensors used to detect the robot's environment (such as detecting objects, distance from objects) and conditions (such as detecting whether the grabbed object has slipped). Specifically, there are distance sensors, visual sensors, force sensors, etc.

The use of intelligent sensing systems has improved the standards of robot mobility, practicality and intelligence. The human perception system is more dexterous than robots for external world information. However, for some privileged information, sensors are more sensitive than robots. Human systems are more efficient.

5. End effector

The end effector is a component connected to the last joint of the manipulator. It is generally used to grab objects, connect with other mechanisms and perform required tasks.

The above is the detailed content of What systems does an industrial robot consist of? What is the role of each?. For more information, please follow other related articles on the PHP Chinese website!

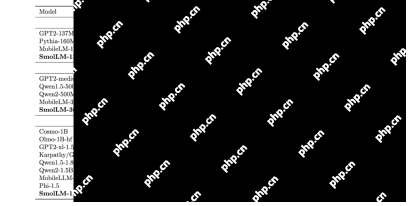

How to Build Your Personal AI Assistant with Huggingface SmolLMApr 18, 2025 am 11:52 AM

How to Build Your Personal AI Assistant with Huggingface SmolLMApr 18, 2025 am 11:52 AMHarness the Power of On-Device AI: Building a Personal Chatbot CLI In the recent past, the concept of a personal AI assistant seemed like science fiction. Imagine Alex, a tech enthusiast, dreaming of a smart, local AI companion—one that doesn't rely

AI For Mental Health Gets Attentively Analyzed Via Exciting New Initiative At Stanford UniversityApr 18, 2025 am 11:49 AM

AI For Mental Health Gets Attentively Analyzed Via Exciting New Initiative At Stanford UniversityApr 18, 2025 am 11:49 AMTheir inaugural launch of AI4MH took place on April 15, 2025, and luminary Dr. Tom Insel, M.D., famed psychiatrist and neuroscientist, served as the kick-off speaker. Dr. Insel is renowned for his outstanding work in mental health research and techno

The 2025 WNBA Draft Class Enters A League Growing And Fighting Online HarassmentApr 18, 2025 am 11:44 AM

The 2025 WNBA Draft Class Enters A League Growing And Fighting Online HarassmentApr 18, 2025 am 11:44 AM"We want to ensure that the WNBA remains a space where everyone, players, fans and corporate partners, feel safe, valued and empowered," Engelbert stated, addressing what has become one of women's sports' most damaging challenges. The anno

Comprehensive Guide to Python Built-in Data Structures - Analytics VidhyaApr 18, 2025 am 11:43 AM

Comprehensive Guide to Python Built-in Data Structures - Analytics VidhyaApr 18, 2025 am 11:43 AMIntroduction Python excels as a programming language, particularly in data science and generative AI. Efficient data manipulation (storage, management, and access) is crucial when dealing with large datasets. We've previously covered numbers and st

First Impressions From OpenAI's New Models Compared To AlternativesApr 18, 2025 am 11:41 AM

First Impressions From OpenAI's New Models Compared To AlternativesApr 18, 2025 am 11:41 AMBefore diving in, an important caveat: AI performance is non-deterministic and highly use-case specific. In simpler terms, Your Mileage May Vary. Don't take this (or any other) article as the final word—instead, test these models on your own scenario

AI Portfolio | How to Build a Portfolio for an AI Career?Apr 18, 2025 am 11:40 AM

AI Portfolio | How to Build a Portfolio for an AI Career?Apr 18, 2025 am 11:40 AMBuilding a Standout AI/ML Portfolio: A Guide for Beginners and Professionals Creating a compelling portfolio is crucial for securing roles in artificial intelligence (AI) and machine learning (ML). This guide provides advice for building a portfolio

What Agentic AI Could Mean For Security OperationsApr 18, 2025 am 11:36 AM

What Agentic AI Could Mean For Security OperationsApr 18, 2025 am 11:36 AMThe result? Burnout, inefficiency, and a widening gap between detection and action. None of this should come as a shock to anyone who works in cybersecurity. The promise of agentic AI has emerged as a potential turning point, though. This new class

Google Versus OpenAI: The AI Fight For StudentsApr 18, 2025 am 11:31 AM

Google Versus OpenAI: The AI Fight For StudentsApr 18, 2025 am 11:31 AMImmediate Impact versus Long-Term Partnership? Two weeks ago OpenAI stepped forward with a powerful short-term offer, granting U.S. and Canadian college students free access to ChatGPT Plus through the end of May 2025. This tool includes GPT‑4o, an a

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

SublimeText3 Chinese version

Chinese version, very easy to use

MinGW - Minimalist GNU for Windows

This project is in the process of being migrated to osdn.net/projects/mingw, you can continue to follow us there. MinGW: A native Windows port of the GNU Compiler Collection (GCC), freely distributable import libraries and header files for building native Windows applications; includes extensions to the MSVC runtime to support C99 functionality. All MinGW software can run on 64-bit Windows platforms.

Dreamweaver CS6

Visual web development tools

mPDF

mPDF is a PHP library that can generate PDF files from UTF-8 encoded HTML. The original author, Ian Back, wrote mPDF to output PDF files "on the fly" from his website and handle different languages. It is slower than original scripts like HTML2FPDF and produces larger files when using Unicode fonts, but supports CSS styles etc. and has a lot of enhancements. Supports almost all languages, including RTL (Arabic and Hebrew) and CJK (Chinese, Japanese and Korean). Supports nested block-level elements (such as P, DIV),

Zend Studio 13.0.1

Powerful PHP integrated development environment