Home >Common Problem >What is a printer photosensitive drum?

What is a printer photosensitive drum?

- 青灯夜游Original

- 2021-12-06 17:08:5922773browse

Printer photosensitive drum refers to the "toner cartridge", which is one of the core components of printer imaging. Its basic structure is generally composed of a basic base material made of aluminum and a photosensitive material coated on the base material. . According to the different photosensitive materials, it can be basically divided into three types: OPC drum (organic photoconductive material), toner drum (Se selenium) and ceramic drum (a-si ceramic).

The operating environment of this tutorial: Windows 7 system, Dell G3 computer.

Printer photosensitive drum refers to the "toner cartridge", which is one of the core components of printer imaging.

The basic structure generally consists of a basic base material made of aluminum, and a photosensitive material coated on the base material.

According to different photosensitive materials, they can be basically divided into three types: OPC drum (organic photoconductive material), toner drum (Se selenium) and ceramic drum (a-si ceramic).

In terms of composition, generally OPC drums only have three layers. The first layer is the aluminum tube, the second layer is the insulating layer, and the third layer is the photosensitive layer. The surfaces of toner drums (Se selenium) and ceramic drums (a-si ceramics) are composed of four to five layers of materials. Especially for ceramic drums, the fourth layer is the first protective layer, the fifth layer is the second protective layer, and the fourth and fifth layers are used to protect the photosensitive layer to ensure the long life of the toner cartridge.

Working Principle

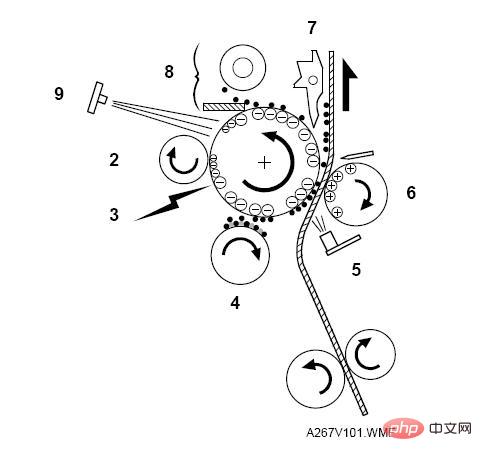

The toner in the toner cartridge is the key to imaging during the printing process, so what makes these toners finally form documents on the page? First we need to understand what latent images are. The toner cartridge is a cylinder whose surface is coated with an organic material (selenium, a rare element). It is pre-charged. When light is irradiated, a resistive reaction occurs in the exposed part. The data signal sent controls the emission of the laser, and the light scanning the surface of the toner cartridge constantly changes, so that some places will be illuminated, the resistance becomes smaller, and the charge disappears, while some places are not illuminated by the light and still retain the charge. , eventually, a latent image composed of electric charges is formed on the surface of the toner drum.

The carbon powder in the toner cartridge is a kind of charged fine resin particles. The charge of the toner powder is opposite to the charge on the surface of the toner cartridge. When the charged toner cartridge When the surface passes through the ink roller, the charged parts adsorb the toner particles, thus turning the latent image into a real image.

When the toner drum rotates during work, the printing system transfers the printing paper, and the printing paper carries a charge with the same polarity as the surface of the toner drum but much stronger. , then the paper passes through the toner drum with toner, and the toner on the surface of the toner drum is attracted to the printing paper, and the image is formed on the surface of the paper. At this time, the toner and printing paper are only combined by the attraction of electric charges. Before the printing paper is sent out of the printer, the toner is melted by high-temperature heating and solidifies on the surface of the paper during the cooling process. After the toner is attached to the printing paper, the toner drum surface continues to rotate and passes through a cleaner to remove the remaining toner so that it can enter the next printing cycle.

For more related knowledge, please visit the FAQ column!

The above is the detailed content of What is a printer photosensitive drum?. For more information, please follow other related articles on the PHP Chinese website!