Technology peripherals

Technology peripherals It Industry

It Industry Paving the way for 1000-layer NAND flash memory manufacturing, Lam launches a new generation of low-temperature dielectric etching technology Lam Cyro 3.0

Paving the way for 1000-layer NAND flash memory manufacturing, Lam launches a new generation of low-temperature dielectric etching technology Lam Cyro 3.0According to news from this website on August 1, Lam Group Lam Research yesterday announced the launch of Lam Cyro 3.0, the third generation low-temperature dielectric etching technology for 3D NAND flash memory manufacturing. "Lam Cryo 3.0 paves the way for (our) customers to achieve 1000-layer 3D NAND," said Sesha Varadarajan, Senior Vice President of Lam's Global Products Division. Lam low-temperature etch has been used in the production of 5 million wafers, and our latest technology is a breakthrough in 3D NAND production. It can create high aspect ratio (High Aspect Ratio) graphic features with angstrom-level precision while reducing environmental impact, and the etching speed is more than twice that of traditional dielectric processes. Lam Cryo 3.0 is the etch technology our customers need to overcome critical NAND manufacturing barriers in the AI era. In the production of existing 3D NAND, layers of memory cells are connected by long, thin vertical vias that run from the top to the bottom of the device. During the channel construction process, even slight atomic-level errors in graphic features and target contours may have a negative impact on the electrical performance of new storage products and may affect the yield.

In addition, compared with traditional dielectric processes, the etching speed of Lam Cryo 3.0 technology is 2.5 times that of the former, energy consumption is reduced by 40%, and emissions are reduced by 90%.

The above is the detailed content of Paving the way for 1000-layer NAND flash memory manufacturing, Lam launches a new generation of low-temperature dielectric etching technology Lam Cyro 3.0. For more information, please follow other related articles on the PHP Chinese website!

业界最高 3.6GB/s 传输速率,美光宣布第九代 276 层 TLC NAND 闪存量产Jul 31, 2024 am 08:05 AM

业界最高 3.6GB/s 传输速率,美光宣布第九代 276 层 TLC NAND 闪存量产Jul 31, 2024 am 08:05 AM本站7月30日消息,美光当地时间今日宣布,其第九代(本站注:276层)3DTLCNAND闪存量产出货。美光表示其G9NAND拥有业界最高的3.6GB/sI/O传输速率(即3600MT/s闪存接口速率),较2400MT/s的现有竞品高出50%,能更好满足数据密集型工作负载对高吞吐量的需求。同时美光的G9NAND在写入带宽和读取带宽方面比市场上的其他解决方案分别高出99%和88%,这一NAND颗粒层面的优势将为固态硬盘和嵌入式存储方案带来性能与能效的提升。此外,与前代美光NAND闪存一样,美光276

三星第 9 代 V-NAND 金属布线量产工艺被曝首次使用钼技术Jul 03, 2024 pm 05:39 PM

三星第 9 代 V-NAND 金属布线量产工艺被曝首次使用钼技术Jul 03, 2024 pm 05:39 PM本站7月3日消息,根据韩媒TheElec报道,三星在其第9代V-NAND的“金属布线”(metalwiring)中首次尝试使用钼(Mo)。本站注:半导体制造过程中八大工艺分别为:晶圆制造氧化光刻刻蚀沉积金属布线测试封装金属布线工艺主要是使用不同的方式连接数十亿个电子元器件,形成不同的半导体(CPU、GPU等),可以说是“为半导体注入了生命”。消息人士称三星公司已从LamResearch公司引进了五台Mo沉积机,此外还计划明年再引进20台设备。除三星电子外,SK海力士、美光和Kioxia等公司也在

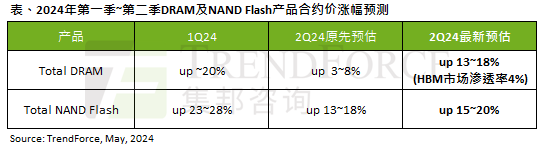

AI 潮影响明显,TrendForce 上修本季度 DRAM 内存、NAND 闪存合约价涨幅预测May 07, 2024 pm 09:58 PM

AI 潮影响明显,TrendForce 上修本季度 DRAM 内存、NAND 闪存合约价涨幅预测May 07, 2024 pm 09:58 PM根据TrendForce的调查报告显示,AI浪潮对DRAM内存和NAND闪存市场带来明显影响。在本站5月7日消息中,TrendForce集邦咨询在今日的最新研报中称该机构调升本季度两类存储产品的合约价格涨幅。具体而言,TrendForce原先预估2024年二季度DRAM内存合约价上涨3~8%,现估计为13~18%;而在NAND闪存方面,原预估上涨13~18%,新预估为15~20%,仅eMMC/UFS涨幅较低,为10%。▲图源TrendForce集邦咨询TrendForce表示,该机构原预计在连续

SK 海力士率先展示 UFS 4.1 通用闪存,基于 V9 TLC NAND 颗粒Aug 09, 2024 am 10:42 AM

SK 海力士率先展示 UFS 4.1 通用闪存,基于 V9 TLC NAND 颗粒Aug 09, 2024 am 10:42 AM本站8月9日消息,根据SK海力士当地时间昨日发布的新闻稿,该企业在FMS2024峰会上展示了系列存储新品,其中就包括尚未正式发布规范的USF4.1通用闪存。根据JEDEC固态技术协会官网,目前已公布的最新UFS规范是2022年8月的UFS4.0。UFS4.0指定了每个设备至高46.4Gbps的理论接口速度,预计USF4.1将在传输速率方面进一步提升。▲JEDECUFS规范页面SK海力士此次展示了两款UFS4.1通用闪存,容量分别为512GB和1TB,均基于321层堆叠的V91TbTLCNAND闪

苹果 iPhone 将用寿命 / 性能更低的 QLC 闪存Jul 26, 2024 am 01:52 AM

苹果 iPhone 将用寿命 / 性能更低的 QLC 闪存Jul 26, 2024 am 01:52 AM根据国外媒体的报道,苹果将会在2026年发布的新iPhone手机上启用更大的存储设计,预计会是2TB。另外,消息称苹果将会使用QLCNAND闪存,原因可能是控制成本。1.存储容量的变化消息称,苹果可能在iPhone16上改变存储容量。不再使用三层单元(TLC)NAND闪存,而是在存储容量达到或超过1TB的机型上使用四层单元(QLC)NAND闪存。2.QLC闪存的优势与TLC相比,QLC的优势在于每个存储单元可以存储四位数据。在使用相同数量的单元时,比TLC储存更多的数据,或者使用更少的单元储存更

消息称三星电子 V9 QLC NAND 闪存尚未获量产就绪许可,影响平泽 P4 工厂规划Jul 31, 2024 pm 08:38 PM

消息称三星电子 V9 QLC NAND 闪存尚未获量产就绪许可,影响平泽 P4 工厂规划Jul 31, 2024 pm 08:38 PM本站7月31日消息,韩媒ZDNetKorea报道称,三星电子V9NAND闪存的QLC版本尚未获得量产许可,对平泽P4工厂的产线建设规划造成了影响。三星电子今年4月宣布其V9NAND闪存的1Tb容量TLC版本实现量产,对应的QLC版本则将于今年下半年进入量产阶段。然而直到现在,三星电子并未对V9QLCNAND闪存下达PRA(本站注:应指ProductionReadinessApproval)量产就绪许可。而容量更高、成本更低的QLC闪存目前正是AI推理服务器存储需求的热点。明星产品前景不明,使得三

TrendForce:预估三季度 NAND 闪存产品合约价涨幅收窄至 5~10%Jun 29, 2024 am 12:54 AM

TrendForce:预估三季度 NAND 闪存产品合约价涨幅收窄至 5~10%Jun 29, 2024 am 12:54 AM本站6月28日消息,TrendForce集邦咨询今日发布最新研报,预估三季度NAND闪存产品合约价的整体涨幅从二季度的15~20%收窄至5~10%。集邦咨询表示,下半年几大原厂积极增产;企业级固态硬盘受惠于服务器订单回升,需求稳定增长,但消费电子领域需求持续不振,导致NAND供过于求更为明显,这也是涨幅减少的主因。▲图源TrendForce集邦咨询本站按类别整理TrendForce集邦咨询预测如下:3DNAND闪存晶圆由于供应回调而买方购买意愿不佳,闪存晶圆现货价格已不到合约价八成。因此三季度闪

三星启动其首批第九代 V-NAND 闪存量产Apr 23, 2024 pm 05:37 PM

三星启动其首批第九代 V-NAND 闪存量产Apr 23, 2024 pm 05:37 PM本站4月23日消息,三星半导体今日宣布,其第九代V-NAND1TbTLC产品开始量产,比三星上一代产品提高约50%的位密度(bitdensity),通过通道孔蚀刻技术(channelholeetching)提高生产效率。凭借当前三星最小的单元尺寸和最薄的叠层厚度,三星第九代V-NAND的位密度比第八代V-NAND提高了约50%。单元干扰避免和单元寿命延长等新技术特性的应用提高了产品的质量和可靠性,而消除虚通道孔则显著减少了存储单元的平面面积。除此外,三星的“通道孔蚀刻”技术通过堆叠模具层来创建电

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

SAP NetWeaver Server Adapter for Eclipse

Integrate Eclipse with SAP NetWeaver application server.

SublimeText3 Linux new version

SublimeText3 Linux latest version

MinGW - Minimalist GNU for Windows

This project is in the process of being migrated to osdn.net/projects/mingw, you can continue to follow us there. MinGW: A native Windows port of the GNU Compiler Collection (GCC), freely distributable import libraries and header files for building native Windows applications; includes extensions to the MSVC runtime to support C99 functionality. All MinGW software can run on 64-bit Windows platforms.

WebStorm Mac version

Useful JavaScript development tools

VSCode Windows 64-bit Download

A free and powerful IDE editor launched by Microsoft