Computer Tutorials

Computer Tutorials Troubleshooting

Troubleshooting Is loading materials under the blast furnace tank a special type of work?

Is loading materials under the blast furnace tank a special type of work?Whether loading materials under the blast furnace trough is a special type of work is a question that many practitioners and employers are concerned about. PHP editor Zimo will give you a detailed introduction to the operation content and hazard factors of loading materials under the blast furnace tank, and analyze whether it belongs to a special type of work based on relevant laws and regulations. By reading this article, you will understand the risks and particularities of this type of work, as well as the corresponding rights and interests protection measures.

1. Is loading materials under the blast furnace tank a special type of work?

The loading of materials under the blast furnace trough is a special type of work, because they all work at high temperatures

2. What are the responsibilities of micromachines for loading materials under the trough?

Hello, the under-trough loading micromachinist is mainly responsible for the operation, maintenance and troubleshooting of the under-trough loading system, including the following responsibilities:

1. Be familiar with the working principles and operating procedures of the under-trough loading system, and be able to correctly Operate equipment for loading and unloading operations.

2. Responsible for the maintenance and upkeep of the loading system under the trough, including cleaning, lubrication, adjustment, etc., to ensure the normal operation of the equipment.

3. Able to detect equipment faults in time and eliminate them to ensure the stability and safety of equipment operation.

4. Responsible for data collection and processing of the under-tank loading system, analysis and statistics of equipment operating data, timely discovery of problems and proposing improvement measures.

5. Cooperate with production management personnel to formulate and implement production plans to ensure production progress and quality.

6. Comply with the company’s safety, environmental protection and quality management systems to ensure safety and environmental protection during equipment operation.

7. Participate in relevant training and learning to continuously improve your skills and knowledge.

3. How to save energy and reduce consumption under the blast furnace tank in an ironmaking plant?

Energy saving under the blast furnace tank mainly involves controlling reasonable screening aperture, using scientific vibrating screen, enhancing screening efficiency, minimizing the entry of powder into the furnace, and finally achieving smooth operation of the blast furnace.

There is also the control of the small particle size of sinter and coke. Some factories use graded feeding into the furnace, which reduces the return rate and saves energy and consumption

4. What's the matter with the blast furnace not being able to pressurize and release materials?

The phenomenon of sudden collapse of the furnace material when it does not drop smoothly is called material collapse. The main factors causing collapse are:

1.

Poor quality of raw fuel. Such as pipe formation or pressure differential increase.

2.

The airflow distribution is abnormal, the edge or center is too heavy, serious deflection, and pipe stroke.

3.

The thermal system fluctuates drastically or the slag alkalinity is too high.

4.

During or after tapping.

5. What are the precautions for the start-up operation of blast furnace belt-type feeding?

1 Walking on a leather belt, it is not allowed to use the belt to transport other non-raw items (including tools, spare parts, oil products, clothing, etc.); when crossing the belt, you should take a safe corridor or go around; 3. Before driving, check whether there are people in various parts or obstacles, otherwise you are not allowed to drive. 4. When the belt conveyor slips and goes deviating, it is prohibited to use pedals, move by hand, push by people or pry with sticks, etc. The machine should be stopped for processing. When electrical equipment fails, you should contact an electrician to deal with it, and you are not allowed to disassemble or install it without permission; 5. The integrity of the safety protection facilities should be checked frequently, and no one is allowed to change the status without permission. When cleaning, you must concentrate on preventing accidentally putting tools, sundries, and clothes into the rotating parts. If a similar situation occurs, you should immediately let go or decisively take off the clothes, cut them off, and stop the machine; you must stop the machine when cleaning the lower part of the belt. , it is strictly forbidden to handle it directly with hands when the roller is glued; 6. Platform guardrails, ladder handrails, roller protective covers, and safety emergency lighting should be inspected frequently. If there is any damage, report it for repair immediately and take temporary remedial measures. Okay6. Where is the card slot on the computer? Because wwan cards have two specifications, one is mini PCI-E and the other is m2, or ngff. It’s easy to tell by appearance (find more common WiFi cards here): The mini PCI-E has two screw holes, on both corners. The screw hole of M2 is half, in the middle. mini PCI-E and mSATA are physically compatible, so the wwan card slot of some notebooks can be installed with mSATA solid state, such as ThinkPad T430. But the premise is that the manufacturer has connected this interface to the motherboard's SATA interface, otherwise it will not be recognized even if the mSATA solid state is plugged in. Pure mini PCI-E solid-state ones are actually available, but I can’t seem to find them for sale now. Someone has posted an article before:Roison An: A rare SSD with Mini PCIe interface (not msata), it comes with Option ROM and can start the system normally

7. How to adjust the machine head on the automatic trough?

The non-adjustable wire covering machine head consists of a machine head shell, a front cover, a back cover, an inner mold, an outer mold, a mold core, and a wiring sleeve. The inner mold and the outer mold of the machine head have a fixed coaxial position structure. The inner cavity of the front cover has evenly distributed through-grooves, so that the wire coating is concentric, the thickness is uniform, the appearance is glossy and the quality is good, and the operation does not need to be adjusted. It is suitable for large quantities. Wire production, and can be matched with various types of rubber and plastic extruders at home and abroad, and has a dedicated waste removal machine

8. How does the blast furnace hoist loading frequency converter accelerate?

Common winch loading has two motors with a wire rope drum, and two frequency converters with one motor each. The frequency converter has a master-slave relationship. The master frequency converter operates at several preset frequencies controlled by switching values. Once the start signal is given, the main frequency converter accelerates to the set frequency according to the set acceleration curve acceleration time, etc.; the slave frequency converter operates in forward and reverse directions. The rotation is controlled by the switching value, while the speed is controlled by the main inverter. During the operation, the analog output port of the main inverter outputs constant analog signals to the slave inverter to achieve synchronization and evenly share the load. 9. How to avoid Loader failure?

If it is a vacuum feeder, you need to pay attention to the operation

Inspection and installation before use are essential

1. Connect the air source and adjust the filter and pressure reduction knob so that the pressure is: 0.55-0.6MPa. When the pressure is lower than 0.5MPa during operation, the pressure can be increased appropriately; if there is water or foreign matter in the filter pressure reducing cup, pour it out and wash it with water before use.

2. Check whether the pneumatic door disc is clean, whether the pneumatic door screws are tight, whether the sealing is intact and regularly check the reliability of door panel installation.

Start and stop:

1. Turn on the power supply of the control cabinet and turn on the emergency stop button under the touch screen and the emergency stop button on the main control cabinet.

2. Select the switch on the main control cabinet to "automatic" mode, click the "motor start" button on the panel to start the water circulation vacuum pump.

3. After the system is powered on, wait for the touch screen to enter the startup interface.

4. Click the EXIT button on the touch screen; enter the main interface;

5. Click the "Run Interface" button in the main interface to enter the running interface;

6. If the system time has been debugged and set, You can start the loading machine to work;

7. Turn off the air source;

8. Press the loading machine operating button to release the remaining air;

9. Turn off the power of the control cabinet.

2. Safety precautions

1. Check whether the air source is clean before use, otherwise it will block the solenoid valve, cylinder, etc., causing the system to not work properly. The air source should also meet the working pressure requirements: 0.55-0.6 MPa.

2. Check whether the air pipe connections at all levels are firm before use. Otherwise, when the air pipe with compressed air falls off, it will swing rapidly and injure people. If this happens, the total air source should be turned off immediately.

3. Before use, check whether the connection of each component is tight; whether the loading machine and the bracket are secure.

4. When the operation of the equipment poses a hazard to the human body and the equipment, the red emergency stop button on the control cabinet door or button box should be pressed immediately.

5. When the vacuum feeding pipeline fails and needs to be suspended, the feeding valve should be closed. When the system fault is eliminated, just open the loading valve.

6. When a liquid circulation vacuum pump/compressor encounters an operating failure, maintenance personnel should be notified immediately for repair.

3. Environmental protection precautions and cleaning instructions

1. Open the quick-install clamp between the upper cover of the feeder and the filter bin, and put the upper cover firmly in place. This part is not in contact with the material, so it only needs to be wiped;

2. Remove the filter, blow off surface materials with compressed air, and clean it thoroughly every week or when changing types;

3. Open the quick-install clamp between the filter bin and the feed bin, and remove the filter bin. Clean the sealing ring;

4. Open the heavy-duty clamp between the material pipeline and the feed bin, open the quick-install clamp between the feed bin and the material door bin, remove the feed bin, clean the inner wall and the inlet Material pipe mouth;

5. Remove the discharge door sealing ring, clean it and reinstall it, paying attention to the sharp edge facing downwards;

6. Clean the pneumatic door and the inner wall of the material door bin;

7. Tighten the pneumatic door plate bolts ;

8. When thoroughly cleaning, the material door bin needs to be removed for cleaning and to prevent water from entering the swing cylinder;

9. After cleaning is completed, install it in order from bottom to top to prevent air leakage.

10. Is there a card slot for a network card on the computer motherboard?

Nowadays network cards are integrated into the motherboard. If the motherboard is broken, you can buy a USB interface to use, or just buy a PCI-E interface to use

The above is the detailed content of Is loading materials under the blast furnace tank a special type of work?. For more information, please follow other related articles on the PHP Chinese website!

Clipchamp Video Loss on Windows? 2 Ways to Recover Files!May 09, 2025 pm 08:12 PM

Clipchamp Video Loss on Windows? 2 Ways to Recover Files!May 09, 2025 pm 08:12 PMRecover Lost Clipchamp Videos: A Step-by-Step Guide Losing a video you've edited in Clipchamp can be frustrating. This guide provides effective methods to recover your lost Clipchamp video files. Finding Your Clipchamp Videos Before attempting recov

7 Useful Fixes for Action Center Keeps Popping upMay 09, 2025 pm 08:07 PM

7 Useful Fixes for Action Center Keeps Popping upMay 09, 2025 pm 08:07 PMAction Center allows you to access quick settings and notifications. However, some users say that they encounter the “Action Center keeps popping up” issue on Windows 11/10. If you are one of them, refer to this post from MiniTool to get solutions.Qu

Instant Ways to Restore Missing Google Chrome Icon on WindowsMay 09, 2025 pm 08:06 PM

Instant Ways to Restore Missing Google Chrome Icon on WindowsMay 09, 2025 pm 08:06 PMTroubleshoot Missing Google Chrome Icon on Windows Can't find your Google Chrome icon on Windows? This guide offers several solutions to restore it. Why is my Chrome icon missing? Several factors can cause the Chrome icon to vanish from your desktop:

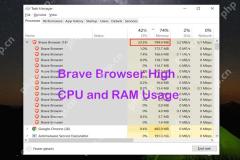

Brave Browser High CPU and RAM Usage: Best 5 Tips to ReduceMay 09, 2025 pm 08:05 PM

Brave Browser High CPU and RAM Usage: Best 5 Tips to ReduceMay 09, 2025 pm 08:05 PMBrave browser CPU and memory usage too high? Under Windows 10/11 system, Brave browser's high CPU and memory usage problems have troubled many users. This tutorial will provide a variety of solutions to help you easily resolve this issue. Quick navigation: Brave browser high CPU and memory footprint Solution 1: Clear cookies and cache data Solution 2: Disable hardware acceleration Solution 3: Close the tab and update the Brave browser Solution 4: Disable the plugin Solution 5: Create a new user profile Optional: Run MiniTool System Booster System Optimization Tool Summarize Brave browser high CP

Targeted Fixes for Xbox Error 0x87e0000f When Installing GamesMay 09, 2025 pm 08:04 PM

Targeted Fixes for Xbox Error 0x87e0000f When Installing GamesMay 09, 2025 pm 08:04 PMTroubleshooting Xbox Error Code 0x87e0000f: A Comprehensive Guide Encountering the Xbox error code 0x87e0000f while downloading games from Xbox Game Pass can be frustrating. This guide provides several solutions to help you resolve this issue and get

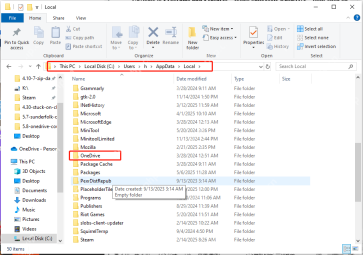

OneDrive Couldn't Start Files on Demand?Top 4 MethodsMay 09, 2025 pm 08:02 PM

OneDrive Couldn't Start Files on Demand?Top 4 MethodsMay 09, 2025 pm 08:02 PMOneDrive Files On-Demand troubleshooting: resolving the "OneDrive couldn't start Files On-Demand" error. This MiniTool guide provides solutions for the persistent "Microsoft OneDrive Couldn’t start files on Demand" error (codes 0x

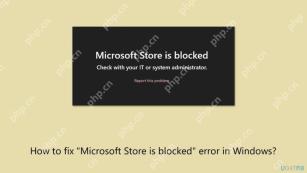

How to fix 'Microsoft Store is blocked' error in Windows?May 09, 2025 pm 06:00 PM

How to fix 'Microsoft Store is blocked' error in Windows?May 09, 2025 pm 06:00 PMMicrosoft Store is blocked error occurs when Windows prevents access to the Microsoft Store app, displaying the message Microsoft Store is blocked. Check with y

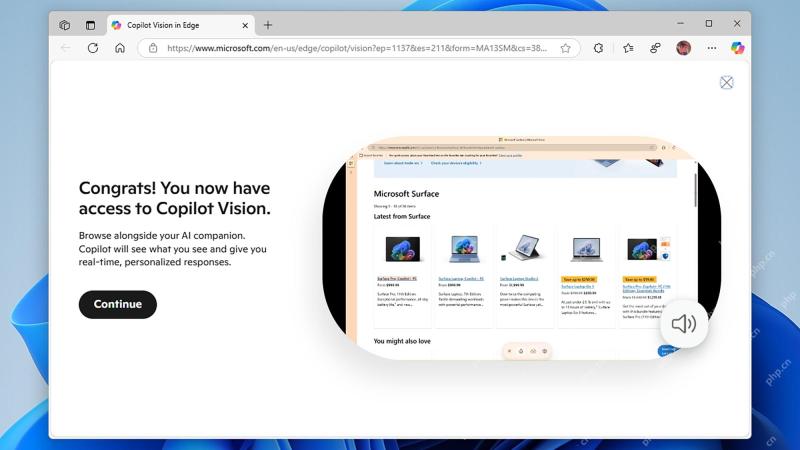

How to use Copilot Vision for free in Microsoft EdgeMay 09, 2025 am 10:32 AM

How to use Copilot Vision for free in Microsoft EdgeMay 09, 2025 am 10:32 AMStaying current with all the new AI tools is a challenge. Many might even overlook readily available AI features. For instance, Copilot Vision is now free for all Microsoft Edge users – a fact easily missed if you don't regularly use Edge or haven't

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

EditPlus Chinese cracked version

Small size, syntax highlighting, does not support code prompt function

SublimeText3 Linux new version

SublimeText3 Linux latest version

mPDF

mPDF is a PHP library that can generate PDF files from UTF-8 encoded HTML. The original author, Ian Back, wrote mPDF to output PDF files "on the fly" from his website and handle different languages. It is slower than original scripts like HTML2FPDF and produces larger files when using Unicode fonts, but supports CSS styles etc. and has a lot of enhancements. Supports almost all languages, including RTL (Arabic and Hebrew) and CJK (Chinese, Japanese and Korean). Supports nested block-level elements (such as P, DIV),

Safe Exam Browser

Safe Exam Browser is a secure browser environment for taking online exams securely. This software turns any computer into a secure workstation. It controls access to any utility and prevents students from using unauthorized resources.

Dreamweaver Mac version

Visual web development tools