Computer Tutorials

Computer Tutorials Troubleshooting

Troubleshooting Requesting documentation: What is commonly used English for mobile phone assembly testing?

Requesting documentation: What is commonly used English for mobile phone assembly testing?Requesting documentation: What is commonly used English for mobile phone assembly testing?

English commonly used in mobile phone assembly testing In the process of mobile phone assembly testing, good language communication is crucial. In order to help everyone understand commonly used English terms, PHP editor Xigua specially compiled the following content, covering key terms and explanations in each link of assembly and testing. By having an in-depth understanding of these terms, you can improve communication efficiency and ensure the smooth progress of assembly and testing work.

IPQC in process quality control Quality control personnel in the process

OQC output quality control Final shipment quality control personnel

IQC incoming quality control Incoming quality control personnel

TQC total quality control Total quality management

PQC passage quality control Section inspection personnel

QA quality assurance Quality assurance personnel

OQA output quality assurance Shipping quality assurance personnel

QE quality engineering Quality engineering personnel

Product assurance category

FAI first article inspection New product first article inspection

FAA first article assurance First article confirmation

CP capability index Capability index

CPK capability process index Process capability index

SSQA standardized supplier quality audit Qualified supplier quality assessment

FMEA failure model effectiveness analysis Failure mode analysis

FQC operation class

AQL Acceptable Quality Level Operation class acceptable quality level

S/S Sample size Sampling Test sample size

ACC Accept Accept

REE Reject

CR Critical

MAJ Major

MIN Minor

Q/R/S Quality/Reliability/Service Quality/Reliability/Service

P/N Part Number

L/N Lot Number Batch number

AOD Accept On Deviation Special Pick

UAI Use As It Special Pick

FPIR First Piece Inspection Report First Piece Inspection Report

PPM Percent Per Million One in a Million

Process Statistical Quality Control

SPC Statistical Process Control Statistical Process Control

SQC Statistical Quality Control Statistical Quality Control

GRR Gauge Reproductive & Repeatability

The reproducibility and retestability of measuring tools determine whether the quantity is reliable

DIM dimension

N Number Number of samples

Other qualities Terminology

QIT Quality Improvement Team Quality Improvement Team

ZD Zero Defect

QI Quality Improvement Quality Improvement

QP Quality Policy Target Policy

TQM Total Quality Management

RMA Return Material Audit Return Material Approval

7QCTools Seven Quality Control Tools Seven Quality Control Techniques

General Category

ECN Engineering Change Notice Engineering Change Notice (for suppliers)

ECO Engineering Change Order Engineering Change Requirement

PCN Process Change Notice Process Change Notice

PMP Product Management Plan Production Control Plan

SOP Standard Operation Procedure Manufacturing Operation Specification

SIP Standard Inspection Procedure Process Inspection Standard Procedure

IS Inspection Specification Finished Product Inspection Specification

BOM Bill Of Material

PS Package Specification

SPEC Specification

DWG Drawing Screen

System File

ES Engineering Standard Engineering Standard

IWS International Workman Standard Process Standard

ISO International Standard Organization International Standard Organization

GS General Specification

Department

PMC Production & Material Control production, material control

MC Material Control

PCC Production control center production control center

PPC Production Plan Control production plan control

DC Document Center Data Center

The above is the detailed content of Requesting documentation: What is commonly used English for mobile phone assembly testing?. For more information, please follow other related articles on the PHP Chinese website!

Clipchamp Video Loss on Windows? 2 Ways to Recover Files!May 09, 2025 pm 08:12 PM

Clipchamp Video Loss on Windows? 2 Ways to Recover Files!May 09, 2025 pm 08:12 PMRecover Lost Clipchamp Videos: A Step-by-Step Guide Losing a video you've edited in Clipchamp can be frustrating. This guide provides effective methods to recover your lost Clipchamp video files. Finding Your Clipchamp Videos Before attempting recov

7 Useful Fixes for Action Center Keeps Popping upMay 09, 2025 pm 08:07 PM

7 Useful Fixes for Action Center Keeps Popping upMay 09, 2025 pm 08:07 PMAction Center allows you to access quick settings and notifications. However, some users say that they encounter the “Action Center keeps popping up” issue on Windows 11/10. If you are one of them, refer to this post from MiniTool to get solutions.Qu

Instant Ways to Restore Missing Google Chrome Icon on WindowsMay 09, 2025 pm 08:06 PM

Instant Ways to Restore Missing Google Chrome Icon on WindowsMay 09, 2025 pm 08:06 PMTroubleshoot Missing Google Chrome Icon on Windows Can't find your Google Chrome icon on Windows? This guide offers several solutions to restore it. Why is my Chrome icon missing? Several factors can cause the Chrome icon to vanish from your desktop:

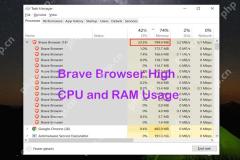

Brave Browser High CPU and RAM Usage: Best 5 Tips to ReduceMay 09, 2025 pm 08:05 PM

Brave Browser High CPU and RAM Usage: Best 5 Tips to ReduceMay 09, 2025 pm 08:05 PMBrave browser CPU and memory usage too high? Under Windows 10/11 system, Brave browser's high CPU and memory usage problems have troubled many users. This tutorial will provide a variety of solutions to help you easily resolve this issue. Quick navigation: Brave browser high CPU and memory footprint Solution 1: Clear cookies and cache data Solution 2: Disable hardware acceleration Solution 3: Close the tab and update the Brave browser Solution 4: Disable the plugin Solution 5: Create a new user profile Optional: Run MiniTool System Booster System Optimization Tool Summarize Brave browser high CP

Targeted Fixes for Xbox Error 0x87e0000f When Installing GamesMay 09, 2025 pm 08:04 PM

Targeted Fixes for Xbox Error 0x87e0000f When Installing GamesMay 09, 2025 pm 08:04 PMTroubleshooting Xbox Error Code 0x87e0000f: A Comprehensive Guide Encountering the Xbox error code 0x87e0000f while downloading games from Xbox Game Pass can be frustrating. This guide provides several solutions to help you resolve this issue and get

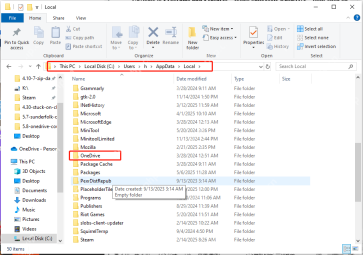

OneDrive Couldn't Start Files on Demand?Top 4 MethodsMay 09, 2025 pm 08:02 PM

OneDrive Couldn't Start Files on Demand?Top 4 MethodsMay 09, 2025 pm 08:02 PMOneDrive Files On-Demand troubleshooting: resolving the "OneDrive couldn't start Files On-Demand" error. This MiniTool guide provides solutions for the persistent "Microsoft OneDrive Couldn’t start files on Demand" error (codes 0x

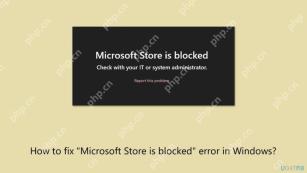

How to fix 'Microsoft Store is blocked' error in Windows?May 09, 2025 pm 06:00 PM

How to fix 'Microsoft Store is blocked' error in Windows?May 09, 2025 pm 06:00 PMMicrosoft Store is blocked error occurs when Windows prevents access to the Microsoft Store app, displaying the message Microsoft Store is blocked. Check with y

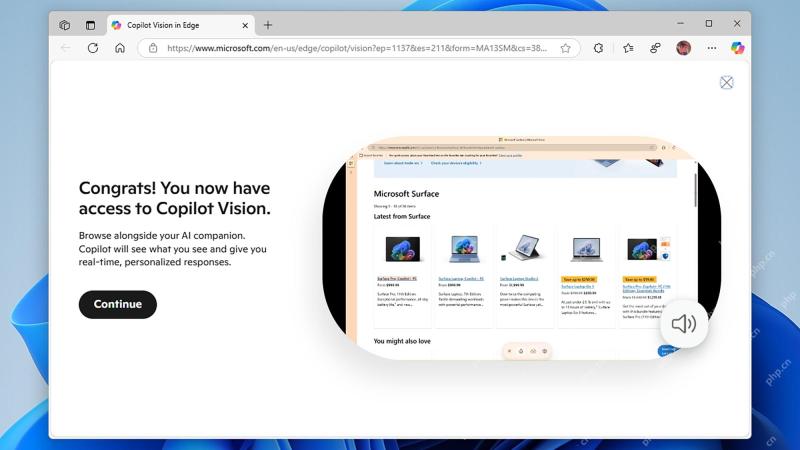

How to use Copilot Vision for free in Microsoft EdgeMay 09, 2025 am 10:32 AM

How to use Copilot Vision for free in Microsoft EdgeMay 09, 2025 am 10:32 AMStaying current with all the new AI tools is a challenge. Many might even overlook readily available AI features. For instance, Copilot Vision is now free for all Microsoft Edge users – a fact easily missed if you don't regularly use Edge or haven't

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

SecLists

SecLists is the ultimate security tester's companion. It is a collection of various types of lists that are frequently used during security assessments, all in one place. SecLists helps make security testing more efficient and productive by conveniently providing all the lists a security tester might need. List types include usernames, passwords, URLs, fuzzing payloads, sensitive data patterns, web shells, and more. The tester can simply pull this repository onto a new test machine and he will have access to every type of list he needs.

mPDF

mPDF is a PHP library that can generate PDF files from UTF-8 encoded HTML. The original author, Ian Back, wrote mPDF to output PDF files "on the fly" from his website and handle different languages. It is slower than original scripts like HTML2FPDF and produces larger files when using Unicode fonts, but supports CSS styles etc. and has a lot of enhancements. Supports almost all languages, including RTL (Arabic and Hebrew) and CJK (Chinese, Japanese and Korean). Supports nested block-level elements (such as P, DIV),

Notepad++7.3.1

Easy-to-use and free code editor

MantisBT

Mantis is an easy-to-deploy web-based defect tracking tool designed to aid in product defect tracking. It requires PHP, MySQL and a web server. Check out our demo and hosting services.

PhpStorm Mac version

The latest (2018.2.1) professional PHP integrated development tool